-

-

-

Total payment:

-

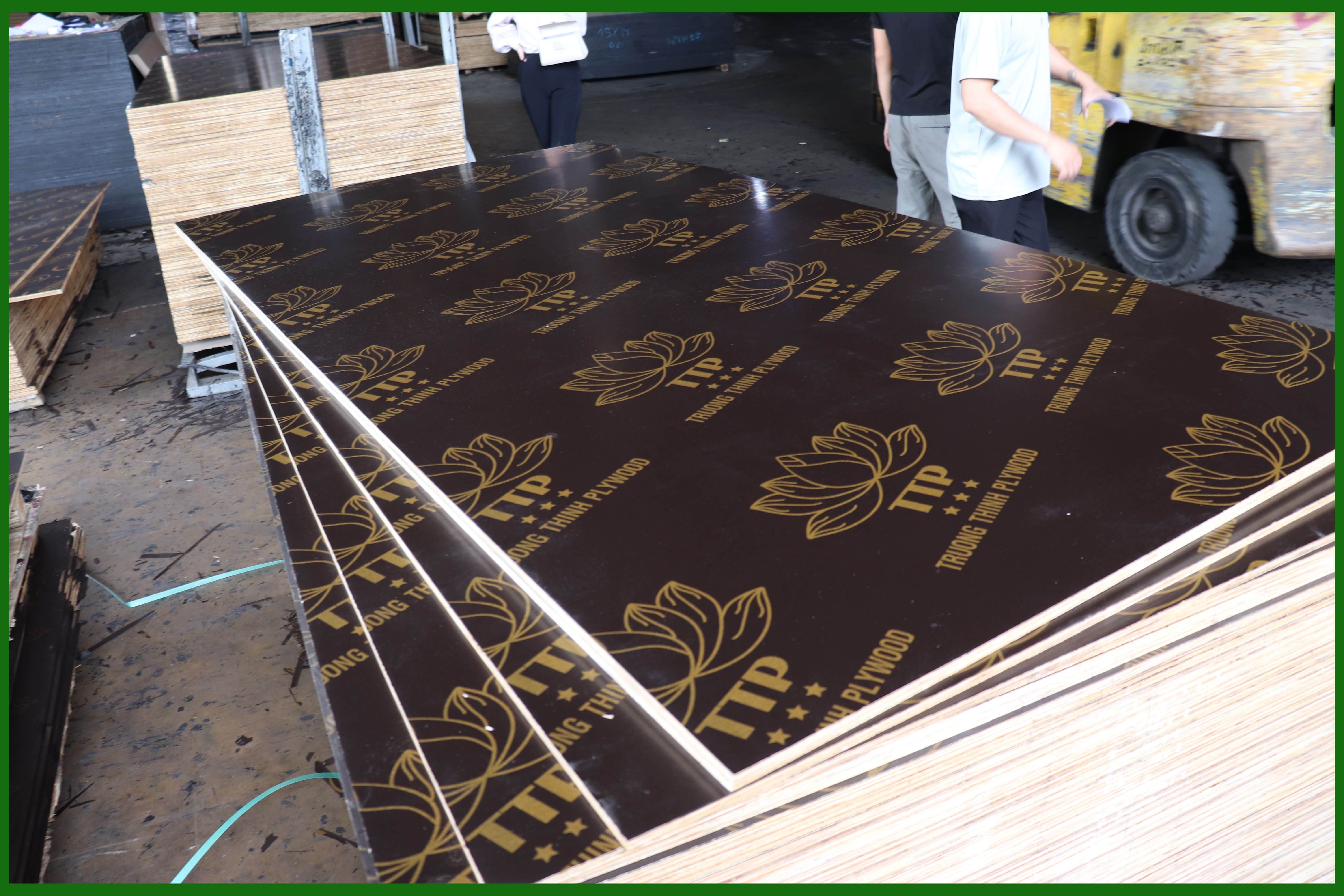

[COMMERCIAL PLYWOOD - EP5. REPAIRING THE SURFACE]

16 Month 04

Before hot pressing, workers will use expert techniques to turn over the board and remove the excess wood at the edge...

Dear Our Valued Customers!

During more than 10 years in this field, I have had the opportunity to go to many places, listen to many customer's stories, I realized that every one have the same difficulty, that is, how to find a reputable, trustworthy plywood manufacturer and supplier.

Aware of that, I decided to establish Truong Thinh Import Export and Trading Business Joint Stock Company (TTP), with the goal of spreading and promoting Vietnamese products and culture to friends around the world.

Personally, a product is not only an ordinary exchangeable commodity, but also a thought and aspiration to affirm Vietnamese cultural value.

Therefore, I look forward to having many opportunities to exchange and cooperate with friends around the world, building the TTP brand - a Vietnamese brand that is different from any others.

TTP has been and will always be with you.

TTP's President,

Mrs. Do Ha

Since the first day of establishment, TTP is committed to bringing best values and services to satisfy all customers. Besides, we appreciate and develop standard business culture with core values: Friendly – Professional – Prestigious – Responsible. Along with always listening, we understand all feedbacks from customers to build strong foundation for TTP activities and ensure harmonious benefits among TTP, Suppliers and Customers.

Company Position

With nearly 10 years of experience in the field of manufacturing, supplying and exporting plywood on the market.

Available Everywhere

Our products are reputable and popular in many countries and regions around the world such as Korea, Japan, Southeast Asia, India, the Middle East, Egypt, Russia....

Quality Products

Manage and control according to strict quality standards from input materials to each pieces of the finished product with modern machinery and equipment and a team of highly skilled workers.

Delivery Schedule Commitment

Owning a factory and a system of long-term cooperative suppliers in the country to meet the huge amount of monthly orders and fast delivery schedule.

Cost-Saving

Optimizing delivery costs thanks to close relationships with shipping lines and logistics companies, helping to get the most competitive final prices for customers.

Enthusiastic Consultation

The staff is dynamic, professional, always willing to support and take care of every customers 24/7.

TTP is proud to introduce product quality certificates that are tested and issued by industry experts and reliable organizations such as Vinacontrol, Kofpi ! During over 10 years in plywood industry, our company always try to serve our customer with most suitable and qualified products, which has been exported to the US, EU, India, Korea, Malaysia, Japan, etc Now constantly we are still trying our best and make effort together day by day to improve our products and services to bring our customers.

10+

YEARS OF EXPERIENCE

25+

EXPORT COUNTRIES

500+

CUSTOMERS

300+

CONTAINERS PER MONTH

![[COMMERCIAL PLYWOOD - EP5. REPAIRING THE SURFACE]](https://bizweb.dktcdn.net/100/350/821/articles/anh-co-vien-2-1-8c2a3b18-fedb-436d-b57b-ac097b042454.jpg?v=1713233700267)

Before hot pressing, workers will use expert techniques to turn over the board and remove the excess wood at the edge...

𝐅𝐢𝐥𝐦 𝐅𝐚𝐜𝐞 𝐏𝐥𝐲𝐰𝐨𝐨𝐝 is a construction material that is formed by pressing large layers of wood together ...

Face/back: Bintangor/Okume/Poplar/Engineer.... Core: acacia, eucalyptus, styrax Glue: MR/WBP E2/E1/E0.. Any size a...

Nationwide delivery

Into money: