-

-

-

Total payment:

-

|

Size |

As customer require |

|

Thickness |

2.5-120mm |

|

Tolerance |

+/- 0.5-1mm |

|

Core Veneer |

Pine, acacia, mixed wood |

|

Face/Back |

No |

|

Glue |

E0, E1, E2 |

|

Moisture content |

Below 18% |

|

Density |

560-650kg/m3 |

|

Application |

making pallets, furniture frame |

Hotline/Whatsapp/Line/Kakao/Wechat:

+84 326 942 288

2.1 Selecting the core veneer

The core is made from Acacia, Styrex, Pine, Eucalyptus,....and mixed wood veneer which are sorted in each bundle following grade A, B, C. Depending on the requirements of the customers, TTP will choose the most suitable kinds of core veneer into production to bring the high quality of each LVL plank.

2.2 Gluing

Every veneer - one by one is put through a glue rolling machine so that the glue is evenly adhered on both sides.

2.3 Arranging the veneer

This is the main point which makes a difference between LVL and Plywood in the manufacturing process. We will arrange the core veneer on the conveyor belt following the same direction and fixed by plastic staples. This veneer lay-up increases the strength of LVL although it is cutted into small sizes

2.4 Cold - pressing

After laying up the veneer, we put it cold pressed for 3-6 hours depending on the weather condition, which helps the panels shape temporarily and solidify the structure inside.

2.5 Hot - pressing

Our factory is using hot pressing machines with the state of the art technology and the high capacity & stable pressing force of 6 cylinders, ensuring flat boards and quite accurate thickness. In turn, putting the panels into each tray of the hot press machine with suitable temperature and pressure heat helps bond the veneer layers together and permanently solidify the product structure.

For the customers who would like to sand the surface to make it more smooth and reduce the thickness tolerance, we also have a sanding machine to meet the customer's requirement.

2.6 Cutting to size

When it comes to LVL (Laminated Veneer Lumber), trimming and cutting is the most important step because each customer often requires different small dimensions.

Our TTP owns a system of modern and high technique LVL cutting machines imported from foreign countries. With the accuracy to every detail, our machine has the capability of cutting every small size dimension as the customer's request. Furthermore, the quality of the first full core taken from the factory is carefully checked by our experienced QC teams before putting it into the cutting machine to maintain the best quality of small sized pieces.

2.7 Inspection

After completing the cutting process, our QC teams will thoroughly inspect the quality of every piece before loading in the container to bring the highly qualified products as well as reduce the maximum defects to customers. We check the surface, edge, moisture content very carefully and especially measure the dimension of LVL which suits the size & tolerance the customers allow. The moisture content we always control is under 18%, it will keep the LVL dried and decrease the moldy rate.

Our TTP is confident of being the only unit which has a 100% LVL piece by piece inspection process before stuffing from professional and highly experienced QC teams with the aim of bringing the best Vietnamese plywood products and value to customers.

2.8 Packaging

Finally, we count and stack up pieces to create a bundle. We use green plastic straps to tie up the bundle and the high strong pallet to make the base, which meets the export standards for delivery by sea. These bundles are ready to be loaded into containers for delivery to customers.

2.9 Loading

Application of LVL Plywood

- LVL used to make pallets or frame of crates

- Furniture: LVL used to make frame of sofa, frame of door, frame of bed

- Contructions: LVL widely used to contructions such as frame of wood, columns, crossbars, flooring, wall and ceiling boards. It has high load capacity and good termite resistance.

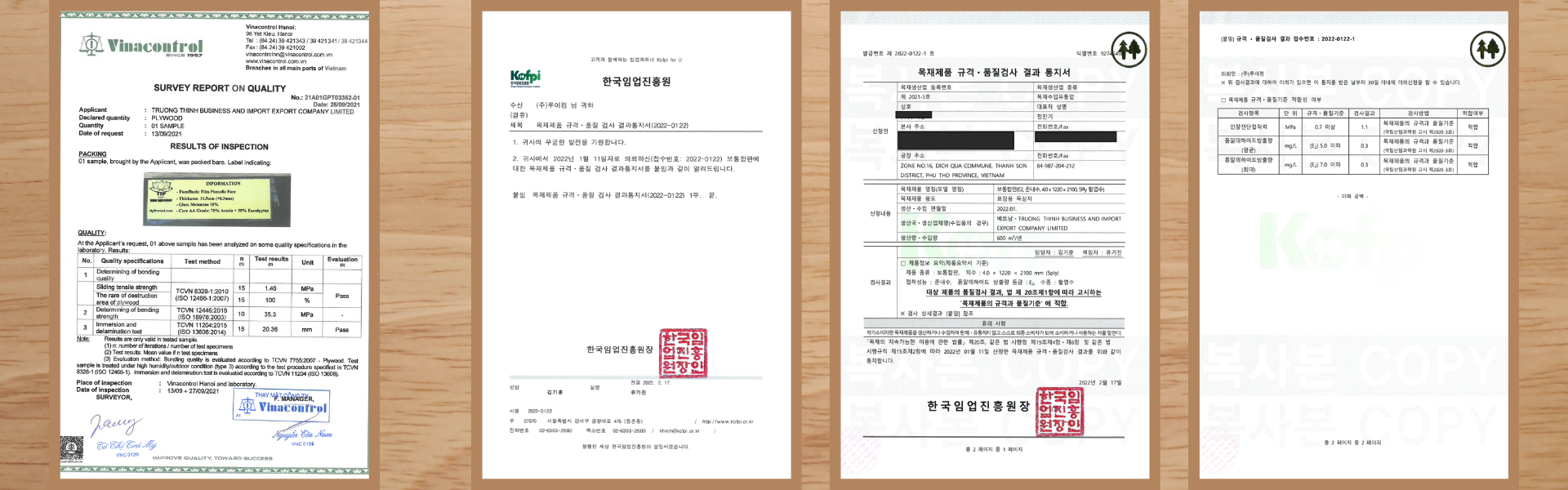

OUR QUALITY CERTIFICATION

During over 10 years in plywood industry, our company always try to serve our customer with most suitable and qualified products. Here are some certificates that indicate the specifications and quality of our plywood, which has been exported to the US, India, Korea, Malaysia, Japan, etc.

------------------------------------------

Hotline/WhatsApp/Line/Kakao: +84 326 942 288

Email: info@ttplywood.com

Website: https://ttplywood.com/

Nationwide delivery

Into money: