-

-

-

Total payment:

-

Introduction to Commercial Plywood

Commercial plywood is a high-quality plywood commonly used in the construction and furniture manufacturing industries. The product is made by pressing thin layers of wood with quality adhesive, then the surface is Commercial and coated with a layer of adhesive to enhance durability and aesthetics. Our Commercial plywood ensures smoothness and flatness, ready for painting or other finishing processes.

Product Information

| Size | 1220x2440mm, 910x1820mm,... |

| Common Thickness |

8.5mm - 4 layers 1.7 mm + 1 layer 2 mm 11.5mm - 7 layers 1.7mm 14.5mm - 9 layers 1.7mm 17.5mm - 11 layers 1.7mm |

| Tolerance | +/-0.3mm |

| Core Grade | A/B/C grade core veneer depending on using purpose |

| Application | High quality packaging, pallet, robbin/cable reels, furniture, construction |

| Glue | MR urea formaldyhe |

| Formaldehyde Emission | E0/E1/E2 |

| Face and Back | Okume 0.25mm, Bintangor 0.13-0.15mm |

| Color | Red |

| Wood Species | Eucalyptus, Acacia, Styrax |

| Technical Info |

1 time cool press 2 times hot press Core sanding 6-8 pitton hot press machines |

| Density | 550-580kgs/m3 |

| Moisture Content | Below 12% |

| Manufacturer | TT PLYWOOD |

Characteristics and Features of Commercial Plywood

Material:

Commercial plywood is made from natural woods such as eucalyptus, pine, or rubber, combined with specialized adhesive, ensuring the board’s durability and stability.

Durability and load-bearing capacity:

- Commercial plywood has good load-bearing capacity, resistant to warping and cracking during use.

- The product is suitable for interior and construction projects requiring durability and high aesthetics.

Smoothness and finishing capability:

The plywood surface is meticulously Commercial, without scratches or roughness, ensuring absolute smoothness, ready for painting, veneering, or other finishing processes.

Practical Applications of Commercial Plywood

In furniture manufacturing:

Commercial plywood is widely used in furniture manufacturing such as tables, chairs, cabinets, beds, and other decorative items.

With a smooth surface and high stability, the product is suitable for veneering or finishing with paint.

In construction:

The product is also applied in construction projects, used for partitions, wall cladding, ceilings, or other decorative applications.

Packaging:

Commercial plywood is also used in the production of packaging, shipping crates, or lightweight structures, thanks to its flexibility and good workability.

Commercial Plywood for Packaging

Reasons to Choose TTPLYWOOD’s Plywood Products

1. High Quality, Meeting International Standards:

TTPLYWOOD’s plywood products are made from high-quality timber sources and undergo rigorous quality control processes. They meet stringent standards, ensuring safety and sustainability in use.

2. Diverse Product Range:

TTPLYWOOD offers a wide variety of plywood products, including film-faced plywood, commercial plywood, LVL, birch core plywood, melamine-coated plywood, and more, suited for various applications in construction, interior design, and packaging.

3. Superior Durability:

TTPLYWOOD plywood stands out for its excellent strength, resistance to warping, and high durability, making it ideal for challenging environments and the climate conditions of Vietnam.

4. Competitive Pricing:

We are committed to delivering high-quality products at reasonable prices. With TTPLYWOOD, customers receive not only a superior product but also optimal cost-efficiency.

5. Attentive After-Sales Service:

TTPLYWOOD is always ready to support customers throughout the product’s usage, with clear warranty policies and flexible return procedures for any issues that may arise.

6. Reliability and Reputation:

TTPLYWOOD is a trusted brand in the plywood market, collaborating with major partners domestically and internationally. We consistently receive positive feedback from our customers for our product quality and dedicated service.

7. Environmental Commitment:

TTPLYWOOD is committed to environmental protection, optimizing production processes to minimize negative impacts on ecosystems.

8. Global Shipping:

With an extensive logistics network, TTPLYWOOD can deliver products to any country, meeting the needs of clients worldwide.

9. Custom Cutting Service:

For added convenience, TTPLYWOOD offers custom-cut plywood services to accommodate specific dimensions as requested, helping save time and costs for projects.

With these strengths, TTPLYWOOD confidently stands as the top choice for quality plywood products, effectively meeting the needs of all customers in construction and interior design.

Production Process

COMMERCIAL PLYWOOD PRODUCTION VIDEO

Production Images at TTPLYWOOD

See more images at the Google Drive

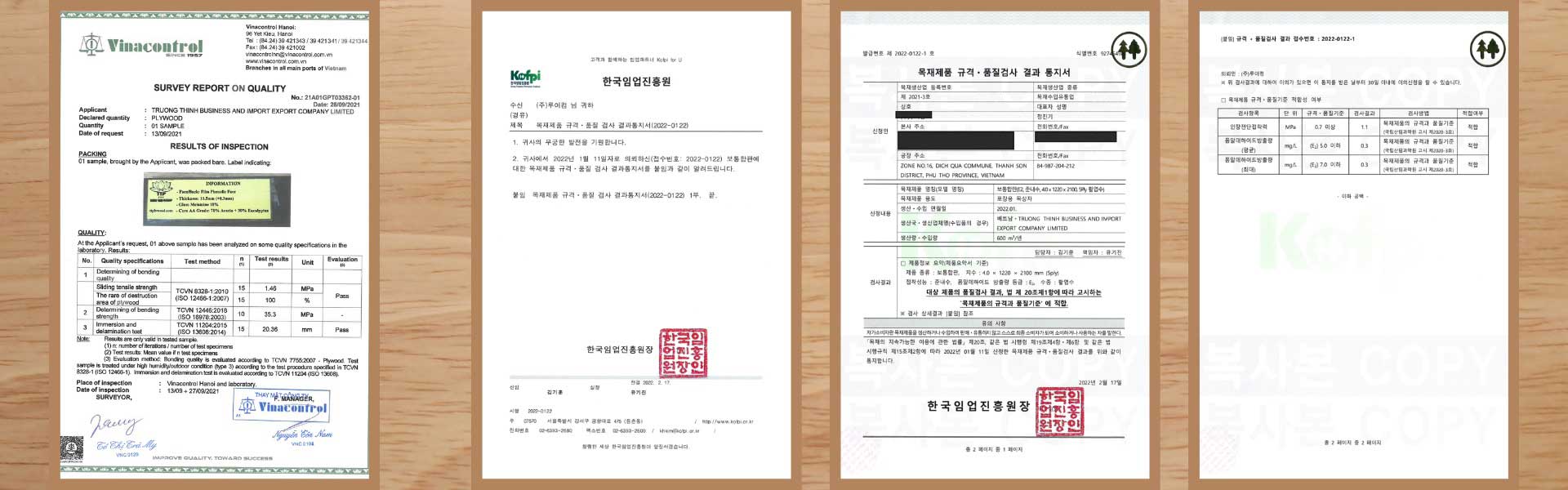

Quality Certifications

With over 10 years of experience in the plywood industry, our company always strives to serve customers with the most suitable and high-quality products. Below are some certifications indicating the technical specifications of our Commercial plywood, which have been exported to South Korea, Malaysia, Japan, the USA, and India.

See some products

- Birch Plywood

- Chip Block

- Commercial Plywood

- Core Plywood

- Film Faced Plywood

- LVL

- Melamine Plywood

- Packing Plywood AB - BC

______________________

Manufacturer and Trading

TRUONG THINH IMPORT EXPORT AND TRADING BUSINESS JOINT STOCK COMPANY

- Office: No LK C34, Hoang Minh Thao Street, Xuan Tao Ward, Bac Tu Liem District, Ha Noi City, Viet nam

- Southern Branch: SAV.1- 02.12 The Sun Avenue building - 28 Mai Chi Tho, An Phu Ward, Thu Duc City, HCM city

- Warehouse: Highway 3, Duc Tu , Dong Anh, Hanoi

- Factory: Area 16, Dich Qua Commune, Thanh Son District, Phu Tho Province

- Hotline/WhatsApp/Line/Kakao: +84 326 942 288

- Email: info@ttplywood.com

- Website: www.ttplywood.com

- Page FB: https://www.facebook.com/ttplywood

- Alibaba: https://ttplywood.trustpass.alibaba.com