-

-

-

Total payment:

-

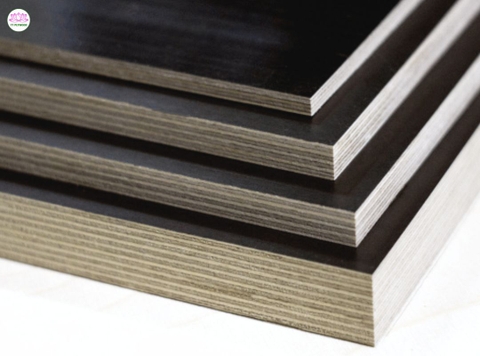

What is Melamine-coated Plywood?

Melamine-coated plywood is a type of engineered wood material created by combining a particleboard or plywood base with decorative paper impregnated with melamine formaldehyde resin. This melamine layer not only enhances moisture and scratch resistance but also provides a smooth, highly aesthetic surface. It should be noted that two types of boards commonly used as cores for melamine-coated panels are Particle Board (PB) and Medium Density Fiberboard (MDF).

The melamine-impregnated decorative paper is pressed onto the board surface under high pressure and temperature to ensure strong adhesion. This pressing process is carried out with precision to avoid peeling or bubbling on the surface. Once the pressing is complete, the surface of the board can feature a variety of colors and patterns, ranging from simple solid colors to intricate designs mimicking wood, stone, or metal.

VIEW DETAILED MELAMINE PLYWOOD PRODUCTION PROCESS

Advantages and Disadvantages of Melamine-coated Plywood

Advantages

- Melamine-coated plywood has high durability, good strength, impact resistance, and is suitable for various applications.

- The surface is scratch-resistant, moisture-resistant, and easy to clean, making it ideal for damp areas such as kitchens and bathrooms.

- It offers a wide range of designs and colors, suitable for many interior styles.

- Environmentally friendly, contributing to forest conservation by using engineered wood.

Disadvantages

- Its water resistance is not completely absolute; it can swell when exposed to water for prolonged periods.

- Seams need to be carefully treated to prevent moisture from seeping in.

- The melamine layer may crack or peel off if subjected to strong, prolonged impacts.

Applications of Melamine Plywood

- Home Furniture: Used for kitchen cabinets, wardrobes, beds, tables, chairs, and bookshelves. These products offer modern, luxurious aesthetics, are easy to clean, and have long-lasting durability.

- Office Furniture: Suitable for desks, filing cabinets, and bookshelves. It provides high durability, scratch resistance, and creates a professional working environment that's easy to maintain.

- Industrial Applications: Used in large-scale projects such as partitions, flooring, speaker boxes, and door frames due to its strength and excellent wear resistance.

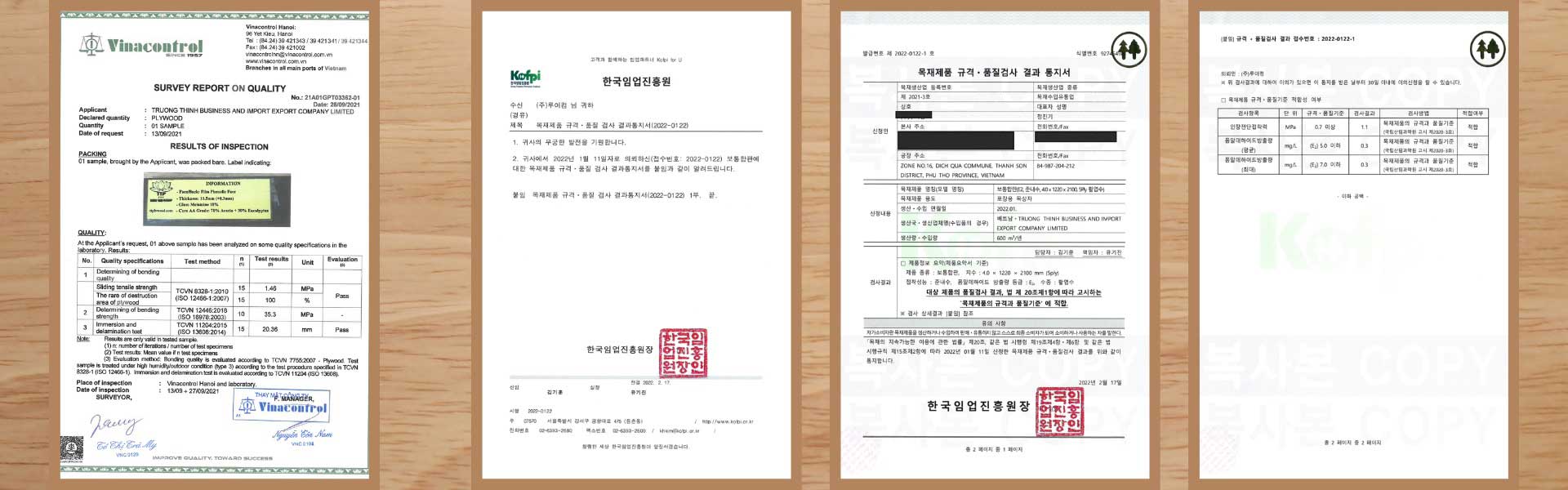

Our quality certification

During over 10 years in plywood industry, our company always try to serve our customer with most suitable and qualified products. Here are some certificates that indicate the specifications and quality of our plywood, which has been exported to the US, India, Korea, Malaysia, Japan, etc.

See some products

_________________________________

Manufacturer and Trading

TRUONG THINH IMPORT EXPORT AND TRADING BUSINESS JOINT STOCK COMPANY

- Office: No LK C34, Hoang Minh Thao Street, Xuan Tao Ward, Bac Tu Liem District, Ha Noi City, Viet nam

- Southern Branch: SAV.1- 02.12 The Sun Avenue building - 28 Mai Chi Tho, An Phu Ward, Thu Duc City, HCM city

- Warehouse: Highway 3, Duc Tu , Dong Anh, Hanoi

- Factory: Area 16, Dich Qua Commune, Thanh Son District, Phu Tho Province

- Hotline/WhatsApp/Line/Kakao: +84 326 942 288

- Email: info@ttplywood.com

- Website: www.ttplywood.com

- Page FB: https://www.facebook.com/ttplywood

- Alibaba: https://ttplywood.trustpass.alibaba.com