-

-

-

Total payment:

-

Definition

Film Faced Plywood is a kind of plywood, which has the face and back made from film with phenol or melamine glue, and the core are made from hardwood. They are strong, and water resistant, suitable for many purposes like construction, furniture,...

Structure

Film faced plywood consists of many thin layers of core veneers bonded together with waterproof glue, like melamine or phenolic glue, then covered with a layer of phenolic or melamine film on the surface to enhance water resistance, abrasion resistance and easy cleaning.

|

Size |

|

|

Thickness |

|

|

Glue |

|

|

Folmadehyde Emission |

|

|

Core |

|

|

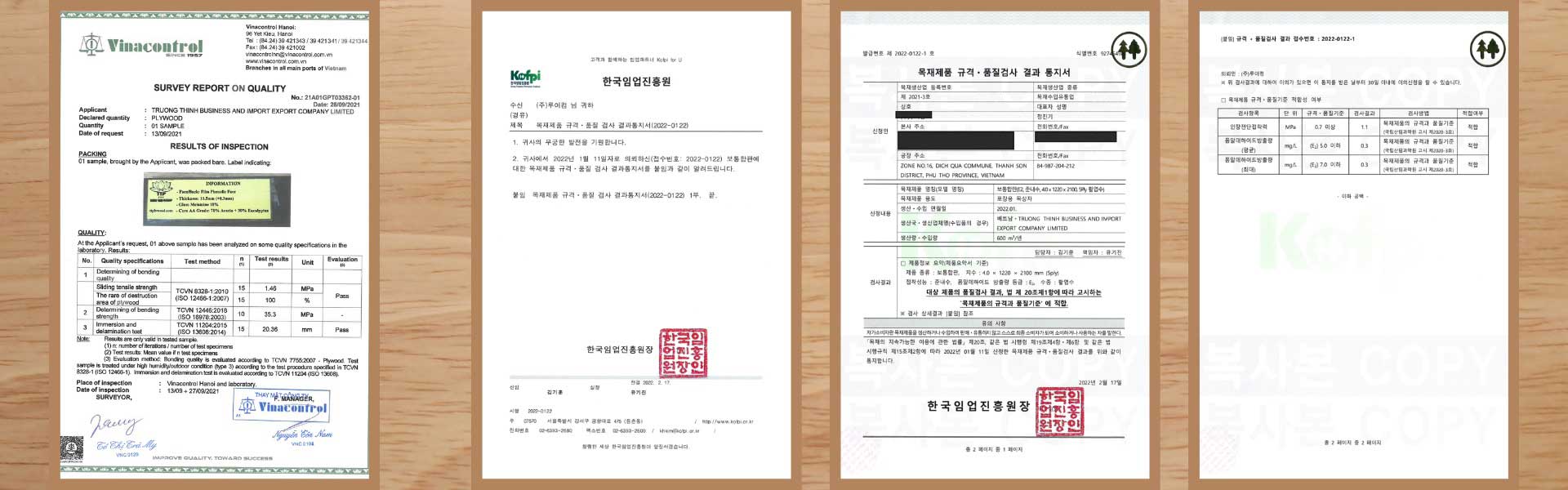

Certificate |

|

|

Color |

|

Building and Construction

Thanks to its increased stability and moisture resistant ability, film faced plywood is perfect for making formwork in construction. The phenolic film layer and acrylic edges make it long lasting and hardly distorted in harsh weather and adverse conditions

Formwork/ Euroform

Shipbuilding Industry

In some cases, film faced plywood is also known as marine plywood. It is made from high quality hardwood, waterproof melamine glue and has light, firm, undefected feature. These qualities make this kind of plywood become a popular choice for boatbuilding, shipbuilding, vessel, container floors and ship parts.

1. High Quality, Meeting International Standards:

TTPLYWOOD’s plywood products are made from high-quality timber sources and undergo rigorous quality control processes. They meet stringent standards, ensuring safety and sustainability in use.

2. Diverse Product Range:

TTPLYWOOD offers a wide variety of plywood products, including film-faced plywood, commercial plywood, LVL, birch core plywood, melamine-coated plywood, and more, suited for various applications in construction, interior design, and packaging.

3. Superior Durability:

TTPLYWOOD plywood stands out for its excellent strength, resistance to warping, and high durability, making it ideal for challenging environments and the climate conditions of Vietnam.

4. Competitive Pricing:

We are committed to delivering high-quality products at reasonable prices. With TTPLYWOOD, customers receive not only a superior product but also optimal cost-efficiency.

5. Attentive After-Sales Service:

TTPLYWOOD is always ready to support customers throughout the product’s usage, with clear warranty policies and flexible return procedures for any issues that may arise.

6. Reliability and Reputation:

TTPLYWOOD is a trusted brand in the plywood market, collaborating with major partners domestically and internationally. We consistently receive positive feedback from our customers for our product quality and dedicated service.

7. Environmental Commitment:

TTPLYWOOD is committed to environmental protection, optimizing production processes to minimize negative impacts on ecosystems.

8. Global Shipping:

With an extensive logistics network, TTPLYWOOD can deliver products to any country, meeting the needs of clients worldwide.

9. Custom Cutting Service:

During over 10 years in plywood industry, our company always try to serve our customer with most suitable and qualified products. Here are some certificates that indicate the specifications and quality of our plywood, which has been exported to the US, India, Korea, Malaysia, Japan, etc.

See some products

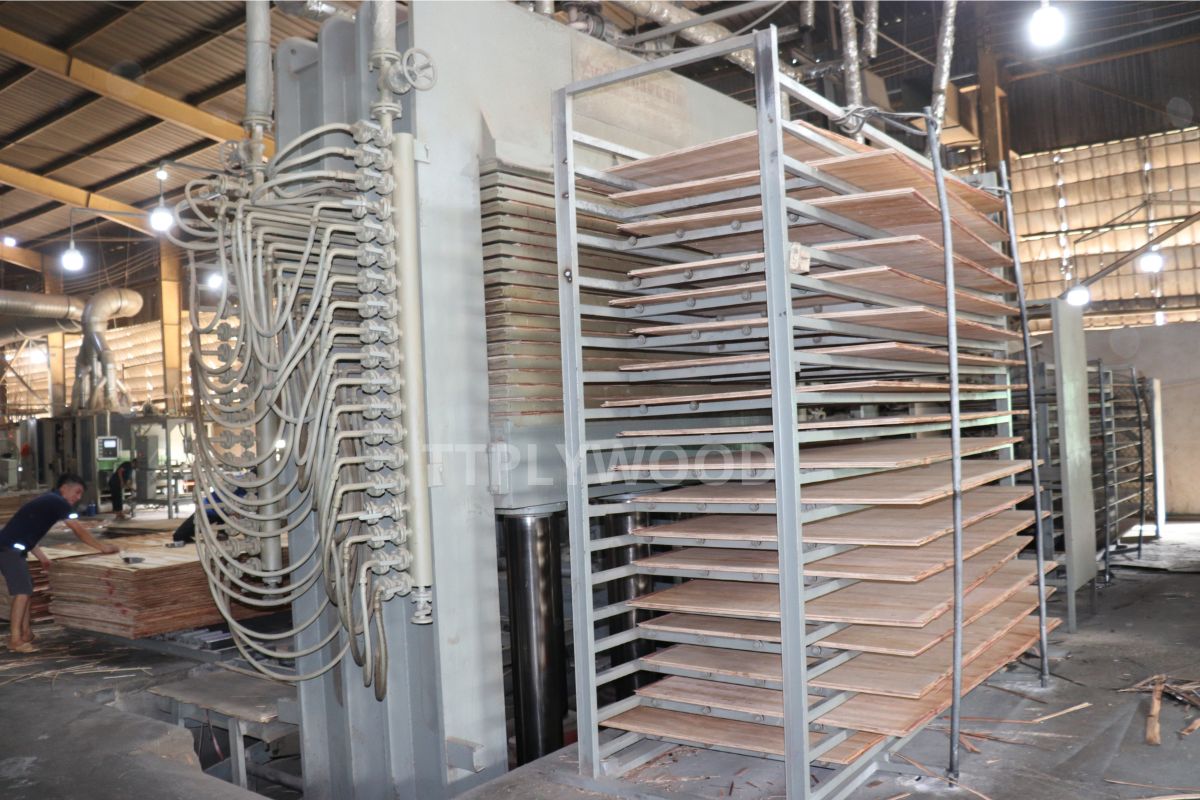

Film faced plywood production process

TRUONG THINH IMPORT EXPORT AND TRADING BUSINESS JOINT STOCK COMPANY

Nationwide delivery

Into money: