-

-

-

Total payment:

-

Product Information

21mm Film Faced Plywood – 13-Layer Panel for Heavy-Duty Construction Applications

Our 21mm film faced plywood is engineered for strength, durability, and performance in demanding construction environments. Built from 13 layers of high-quality veneers, this panel delivers exceptional load-bearing capacity and resistance to warping, cracking, and moisture—making it the ideal choice for concrete formwork and heavy-duty scaffolding systems.

Each sheet is coated with a smooth phenolic or melamine film on both sides, providing a waterproof and abrasion-resistant surface. The edges are sealed with waterproof paint, enhancing protection during repeated use in outdoor or high-humidity conditions.

We offer options compliant with E0, E1, or E2 formaldehyde emission standards, allowing you to select the right grade for your local regulations and environmental requirements. This makes it suitable not only for domestic construction but also for export to markets in the EU, Middle East, and North America.

- Thickness: 21mm

- Construction: 13-ply for superior core integrity

- Surface: Double-sided film faced (black/brown)

- Formaldehyde Emission: E0 / E1 / E2

- Applications: Concrete casting, formwork, scaffolding decks, floor systems

- Reusability: Up to 10–20 times with proper handling

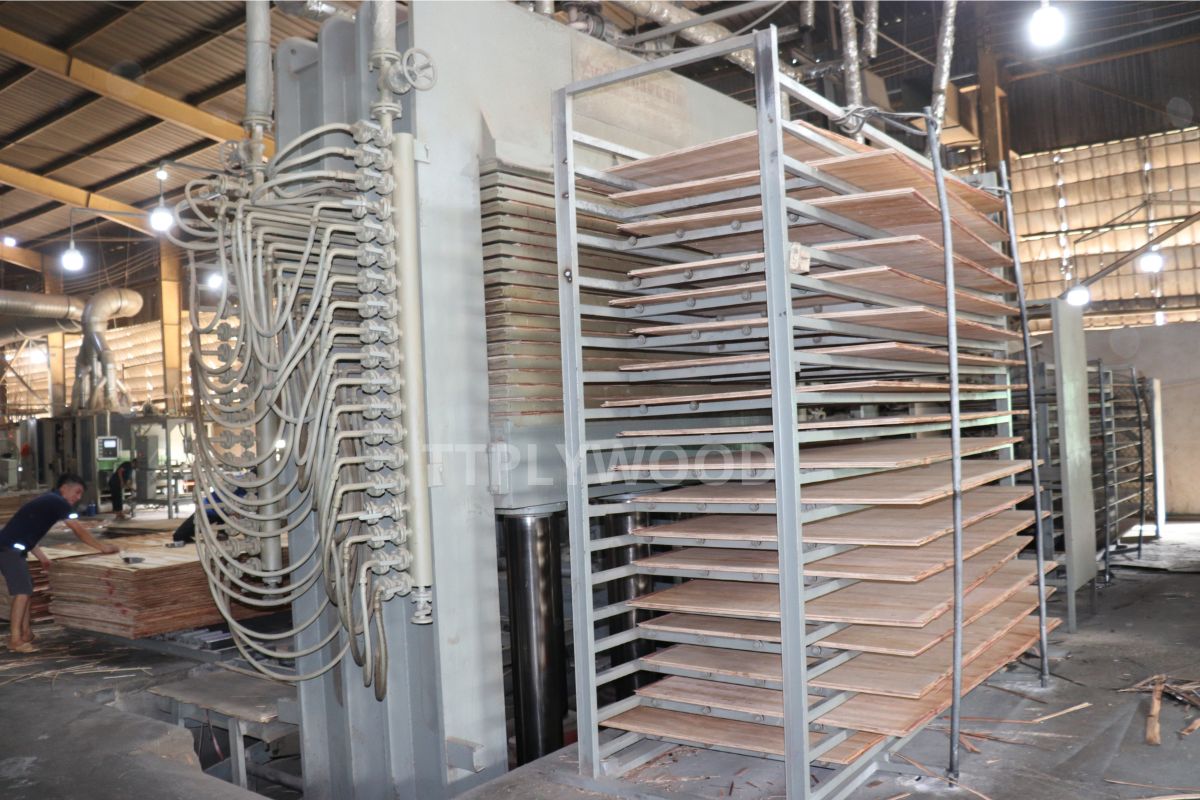

See how it’s made: Watch our factory process in action – from veneer assembly to hot pressing and final quality check.

(Film Faced Plywood production process)

When you need plywood that performs under pressure, TT Plywood’s 21mm film faced panels are built to deliver consistently, globally.

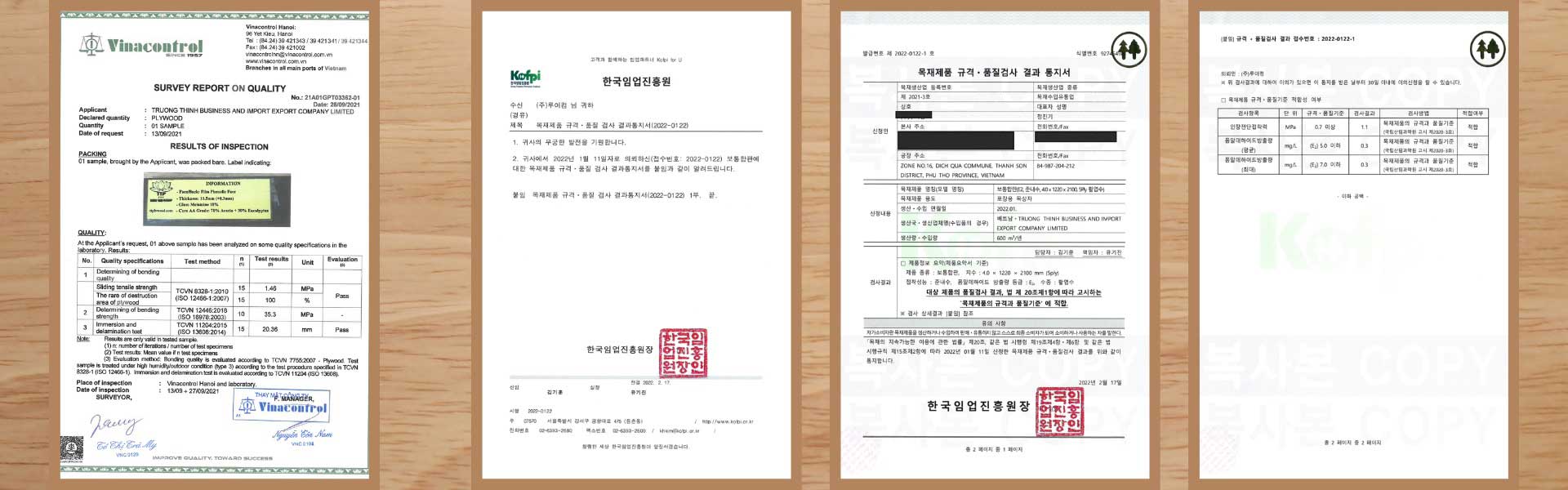

Our quality certification

During over 10 years in plywood industry, our company always try to serve our customer with most suitable and qualified products. Here are some certificates that indicate the specifications and quality of our plywood, which has been exported to the US, India, Korea, Malaysia, Japan, etc.

See some products

Production Images at TTPLYWOOD

See more images at the Google Drive

_________________________________

Manufacturer and Trading

TRUONG THINH IMPORT EXPORT AND TRADING BUSINESS JOINT STOCK COMPANY

- Office: No LK C34, Hoang Minh Thao Street, Xuan Tao Ward, Bac Tu Liem District, Ha Noi City, Viet nam

- Southern Branch: SAV.1- 02.12 The Sun Avenue building - 28 Mai Chi Tho, An Phu Ward, Thu Duc City, HCM city

- Warehouse: Highway 3, Duc Tu , Dong Anh, Hanoi

- Factory: Area 16, Dich Qua Commune, Thanh Son District, Phu Tho Province

- Hotline/WhatsApp/Line/Kakao: +84 326 942 288

- Email: info@ttplywood.com

- Website: www.ttplywood.com

- Page FB: https://www.facebook.com/ttplywood

- Alibaba: https://ttplywood.trustpass.alibaba.com