-

-

-

Total payment:

-

General Information

What is chip block?

Chip block is a products mainly used in packaging industries, for making pallet foot. It is made by mixing the saw-dust and glue, and then compressed into a mold, and then cutting into the required sizes.

| Type | with hole or no hole |

| Size | width/length 70 mm -140 mm |

| Tolerance | +/- 0.5 mm - 1 mm |

| Materials | Sawdust from Pine, acacia wood... |

| Height | As required |

| Moisture content | Below 12% |

| Glue | E2 |

| Density | 560-650kg/m3 |

| Applications | making pallet foot,... |

Applications of Chip block

Chip block's most popular application is to make pallet foot. because of many advantages such as:

- Increase the weight capacity of the pallet

- Easy to move and protect goods in transit

- Helps reduce the cost of goods and increase competitiveness in the market

Production Process

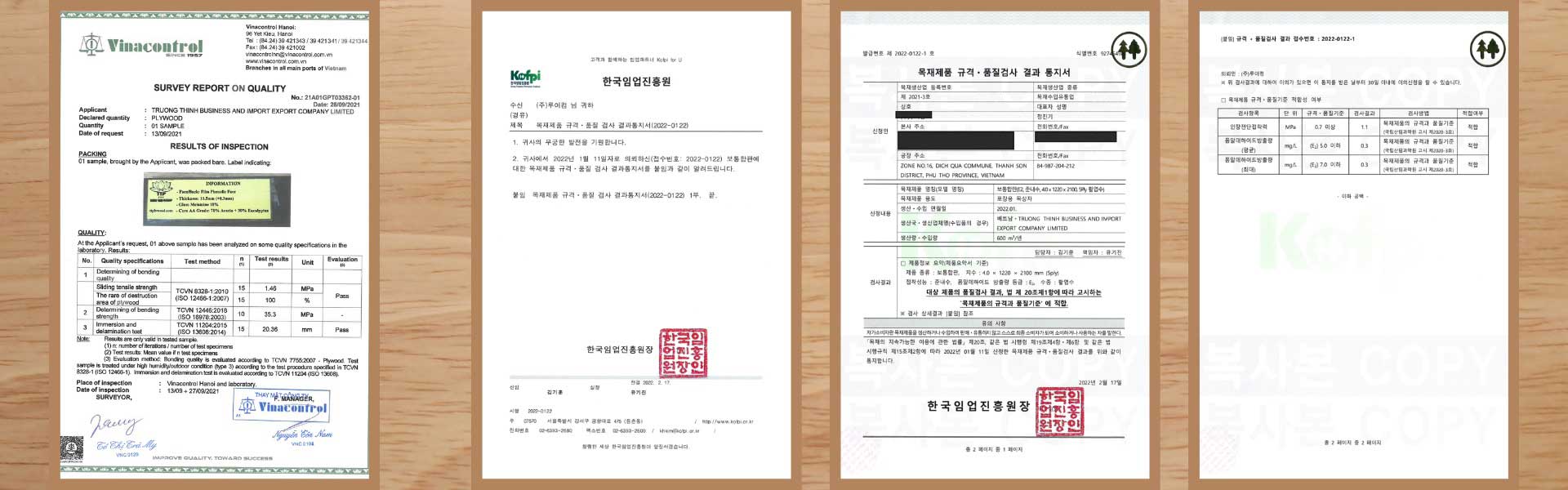

Quality Certifications

During over 10 years in plywood industry, our company always try to serve our customer with most suitable and qualified products. Here are some certificates that indicate the specifications and quality of our plywood, which has been exported to the US, India, Korea, Malaysia, Japan, etc.

_______________________

Manufacturer and Trading

TRUONG THINH IMPORT EXPORT AND TRADING BUSINESS JOINT STOCK COMPANY

- Office: No LK C34, Hoang Minh Thao Street, Xuan Tao Ward, Bac Tu Liem District, Ha Noi City, Viet nam

- Southern Branch: SAV.1- 02.12 The Sun Avenue building - 28 Mai Chi Tho, An Phu Ward, Thu Duc City, HCM city

- Warehouse: Highway 3, Duc Tu , Dong Anh, Hanoi

- Factory: Area 16, Dich Qua Commune, Thanh Son District, Phu Tho Province

- Hotline/WhatsApp/Line/Kakao: +84 326 942 288

- Email: info@ttplywood.com

- Website: www.ttplywood.com

- Page FB: https://www.facebook.com/ttplywood

- Alibaba: https://ttplywood.trustpass.alibaba.com