-

-

-

Total payment:

-

15mm Film Faced Plywood – 11-Layer Panel for Efficient and Reusable Formwork

Our 15mm film faced plywood is a reliable, cost-effective solution for medium-duty construction tasks such as concrete formwork, scaffolding bases, and general structural applications. Constructed from 11 layers of high-quality veneers, it offers a strong, stable core with excellent dimensional accuracy.

Both surfaces are coated with a durable phenolic or melamine film that resists moisture, abrasion, and chemical exposure. Edges are sealed with waterproof paint to prevent delamination and extend panel lifespan during repeated uses in humid or outdoor environments.

With formaldehyde emission options of E0, E1, or E2, this product complies with environmental regulations across global markets including Europe, the Middle East, and North America.

Specifications:

- Thickness: 15mm

- Construction: 11-ply for improved strength and stability

- Surface: Film faced both sides (black or brown film)

- Glue: WBP (phenolic/melamine)

- Formaldehyde Emission: E0 / E1 / E2

- Applications: Medium-load concrete formwork, scaffolding bases, general construction use

- Reusability: Up to 8–15 times with proper use and handling

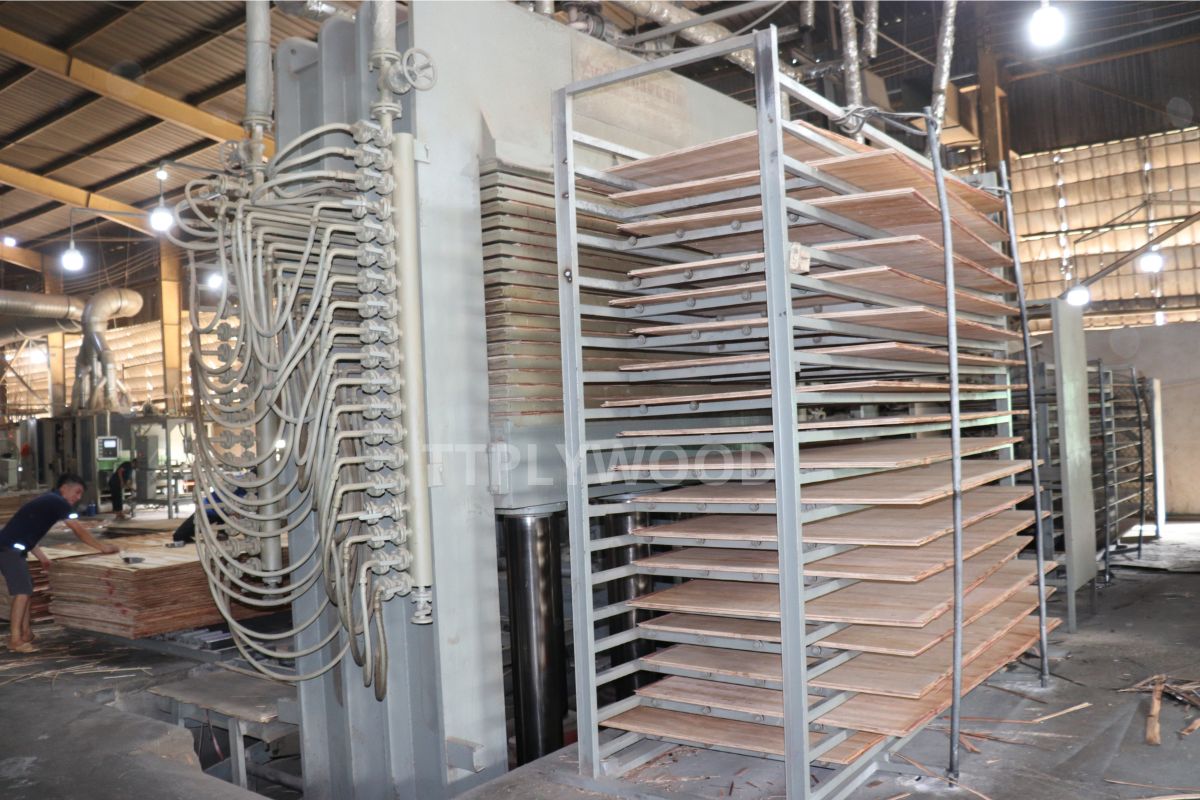

See how it’s made: Explore our detailed production process from veneer preparation to surface coating and quality inspection.

(Film faced plywood production process)

Applications

15mm film faced plywood is widely used in the construction and infrastructure sectors thanks to its reusability and strength:

• Concrete Formwork: Ideal for forming walls, slabs, and beams

• Scaffolding Bases: Stable platform for scaffold systems

• Flooring Systems: Subflooring in temporary or semi-permanent structures

• Site Hoardings & Temporary Fencing: Durable for outdoor use

• Packaging & Pallets: Industrial-grade crates and support panels

• Bracing & Sheathing: General reinforcement in construction projects

Our Quality

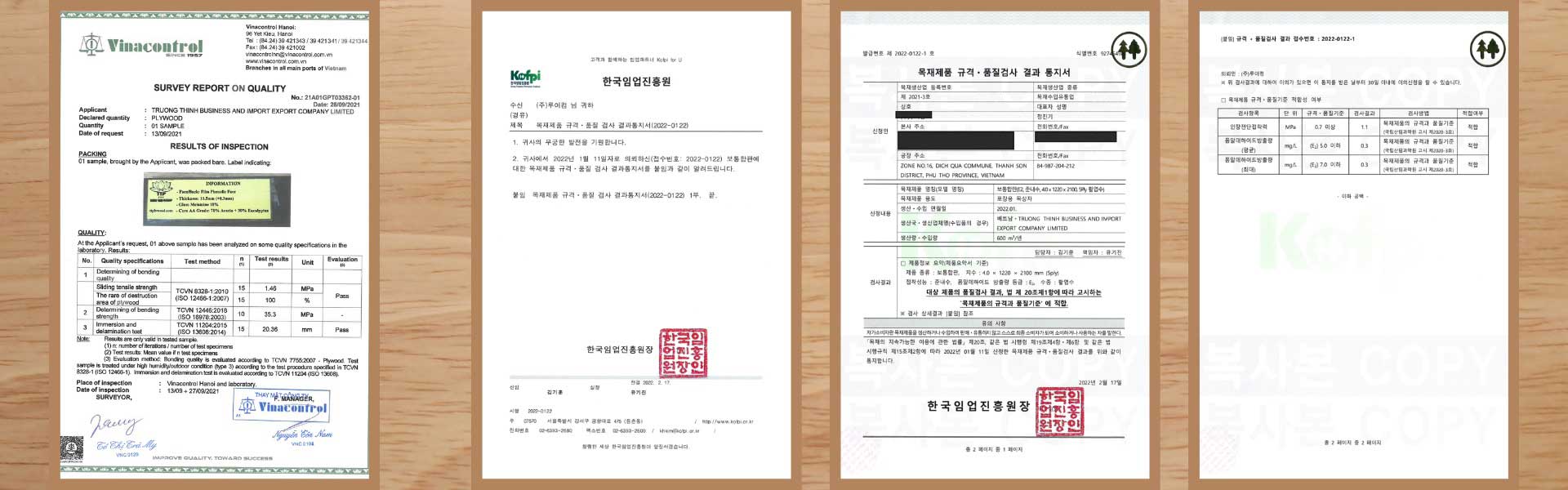

With over a decade of experience in the plywood industry, TT Plywood is proud to supply products that meet strict international standards. Our film faced plywood is certified for export to countries such as the US, India, Korea, Malaysia, and Japan. Certification documents available upon request include:

• FSC® – Forest Stewardship Council

• CARB P2 – California Air Resources Board

• CE Marking – EN13986 compliance

• E0/E1 glue test reports

Our certification

During over 10 years in plywood industry, our company always try to serve our customer with most suitable and qualified products. Here are some certificates that indicate the specifications and quality of our plywood, which has been exported to the US, India, Korea, Malaysia, Japan, etc.

See some products

Production Images at TTPLYWOOD

_________________________________

Manufacturer and Trading

TRUONG THINH IMPORT EXPORT AND TRADING BUSINESS JOINT STOCK COMPANY

- Office: No LK C34, Hoang Minh Thao Street, Xuan Tao Ward, Bac Tu Liem District, Ha Noi City, Viet nam

- Southern Branch: SAV.1- 02.12 The Sun Avenue building - 28 Mai Chi Tho, An Phu Ward, Thu Duc City, HCM city

- Warehouse: Highway 3, Duc Tu , Dong Anh, Hanoi

- Factory: Area 16, Dich Qua Commune, Thanh Son District, Phu Tho Province

- Hotline/WhatsApp/Line/Kakao: +84 326 942 288

- Email: info@ttplywood.com

- Website: www.ttplywood.com

- Page FB: https://www.facebook.com/ttplywood

- Alibaba: https://ttplywood.trustpass.alibaba.com