-

-

-

Total payment:

-

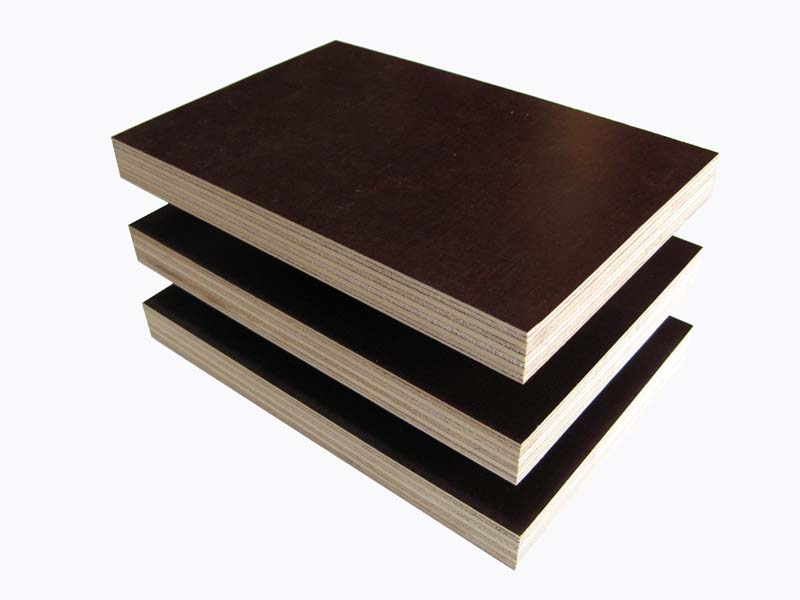

FILM FACED PLYWOOD USED IN CONSTRUCTION WORK

Posted by Đỗ Tiến Hải at 07/03/2022

Building templates are the mold shell and holder that assist concrete casting and forming, which can be seen everywhere in the construction sites. The main building templates currently on the market are still film faced plywoods and steel molding plates. Compared with the steel molding plate, the advantages of film faced plywood are mainly reflected in the following three aspects

𝟏. 𝐒𝐡𝐨𝐫𝐭 𝐂𝐨𝐧𝐬𝐭𝐫𝐮𝐜𝐭𝐢𝐨𝐧 𝐏𝐞𝐫𝐢𝐨𝐝

The short construction period of film faced plywood ( FFP) is mainly benefits from its characteristics.

- Firstly, the FFP is easy to demoulding. It takes only one-seventh as long to demould the film faced plywood as the steel one. This can effectively accelerate the progress of the construction project. At the same time, it will also bring further cost saving

- Secondly, the surface of film face plywood is smooth. There is no need for carrying out secondary plastering, which means using the FFP as moulding material will reduce the construction procedures and the workload of workers.

- Thirdly, film faced plywood has good thermal insulation property. In winter, it can effectively protect the concrete which is in the process of solidification, and prevent them from freezing off. That will ensure the quality of the construction project and prevent rework costs.

𝟐. 𝐋𝐢𝐠𝐡𝐭 𝐏𝐞𝐫 𝐔𝐧𝐢𝐭 𝐖𝐞𝐢𝐠𝐡𝐭 𝐚𝐧𝐝 𝐇𝐢𝐠𝐡 𝐒𝐭𝐫𝐞𝐧𝐠𝐭𝐡

As its name indicates, the basic material of WBP Film Faced Plywood is wood. Therefore its unit weight is much lighter than steel molding plate. The manufacturer processes the log, then drys and hot-pressing them. These processes help the film faced plywood retains a good structural strength with its light per unit weight. It can fully meet the construction needs. The lighter unit weight also makes carry and assemble becomes easier. FFP is especially suitable for the construction of high-rise buildings and bridges.

𝟑. 𝐆𝐨𝐨𝐝 𝐂𝐨𝐫𝐫𝐨𝐬𝐢𝐨𝐧 𝐑𝐞𝐬𝐢𝐬𝐭𝐚𝐧𝐜𝐞

The outdoor film faced plywood is made by WBP glue and covered with PVC film paper. Its appearance and physical properties can be kept for a long time even in a wet or moist environment. Its outer surface is smooth and not easy to break or fall off, which means you don't need to worry that it may contaminate the concrete.

Besides, the FFP can be sawed, nailed, or be combined into different shapes according to the construction needs. Generally speaking, outdoor film faced plywood can be used repeatedly for more than 15 times. It is these advantages that make the FFP quickly recognized by consumers in recent years, and also occupies a growing market share now.

As a consumer, what you also need to pay attention to is the quality, to reduce the risk of a construction accident. Making sure that you choose the manufacturers and brands with production qualifications.

--------------------------------------------

If you are interested in plywood, please don't hesitate to contact us:- Hotline/WhatsApp/Line/Kakao: +84 866 969 398 / +84 934 482 488

- Email: sales@ttplywood.com

- Fanpage: TT Plywood

- Instagram: tt_plywood

- Website: https://ttplywood.com/

- Alibaba: https://ttplywood.trustpass.alibaba.com/

Read more: 3 INTERESTING THINGS ABOUT PLYWOOD THAT YOU MAY NOT KNOW

Tags :

birch plywood

box

cheap plywood

Commercial plywood

construction plywood

crate

EXPORT PLYWOOD

FFP

film faced plywood

frames

Furniture plywood

LVL

Marine plywood

packing plywood

pallet

pine face

plywood

PLYWOODVIETNAM

tego

TTP

TTPLYWOOD

TT PLYWOOD

types of plywood

VENEER

Vietnamese plywood