-

-

-

Total payment:

-

COMMERCIAL PLYWOOD PRODUCTION VIDEO

COMMERCIAL PLYWOOD PRODUCTION DETAILS

| Size | 1220x2440mm, 910x1820mm,…. |

|

Common Thickness

|

8.5mm - 4 layers 1.7 mm + 1 layer 2 mm 11.5mm - 7 layers 1.7mm 14.5mm - 9 layers 1.7mm 17.5mm - 11 layers 1.7mm |

| Tolerance | +/-0.3mm |

| Core Grade | A/B/C grade core veneer depending on using purpose |

| Application | High quality packaging, pallet, robbin/cable reels, furniture, construction |

| Glue | MR urea formaldyhe |

| Formaldehyde Emission | E0/E1/E2 |

| Face and Back | Bintangor 0.13-0.15mm |

| Color | Red |

| Wood Species | Eucalyptus, Acacia, Styrax |

|

Technical Info

|

1 time cool press 2 times hot press Core sanding 6-8 pitton hot press machines |

| Density | 550-580kgs/m3 |

| Moisture Content | Below 12% |

Hotline/Whatsapp/Line/Kakao/Wechat:

+84 326 942 288

COMMERCIAL PLYWOOD PRODUCTION DETAILS

2.1 Selecting the core veneer

For commercial plywood, we pay a lot of attention to the selection of raw materials because it is one of the most important materials to make a good board. No matter how good the quality of the glue or the face is, the poor core veneer cannot produce a perfect plywood board.

Our core veneer has grade A, B, C which are peeled off from eucalyptus, acacia, styrax… Each veneer is very thin with thickness of 1.7mm to 2mm, and the standard moisture content for manufacturing must be below 18%. As per the customer's requirements, we will choose the kinds of veneer suitable for the production of commercial plywood for every different purpose.

If you would like a beautiful bright surface without holes or torn, especially good pressure resistance, core veneer grade A is a good choice for you.

2.2 Gluing

The veneer is spread by a glue rolling machine one by one so that the glue is evenly adhered on both sides of the veneer. Peeled boards that are not evenly glued will lead to delamination and edge separation if put into production.

2.3 Arranging the veneer

Layering the veneer is very important, which can be considered as an art because if the veneers are not properly arranged, the finished plywood becomes weak, easily warped and broken.

We arrange the piece by staggered criss-cross to create a solid structure for commercial plywood. Two layers next to the face will be attached with plastic staplers to prevent jostling. The number of layers of veneers depends on the required thickness of the board.

2.4 Cold - pressing

- After laying up the veneer, we put it cold pressed for 3-6 hours depending on the weather condition, which helps the panels shape temporarily and solidify the structure inside.

2.5 Repairing the surface

Before hot pressing, workers will use expert techniques to turn over the board and remove the excess wood at the edges and veneer overlap on the surface.

2.6 First time of Hot - pressing

Our factory is using hot pressing machines with the state of the art technology and the high capacity & stable pressing force of 6 cylinders, ensuring flat boards and quite accurate thickness. In turn, putting the panels into each tray of the hot press machine with suitable temperature and pressure heat helps bond the veneer layers together and permanently solidify the product structure

The hot-pressing time depends on every thickness & the weather condition

for about 20 to 50 minutes.

2.7 Puttying the surface

We knock on the pressed core board then use putty to seal the small holes. After applying the putty, we let it dry for 1 day.

2.8 Sanding

In order to make the plywood’s surface smooth, TTP’s factory always sands both sides of the panel by the sanding machine and each side is sanded 2 times to remove all rough and uneven parts.

2.9 Sticking the face veneer

After sanding the surface, we glue both sides of the sheets and stick the face veneer.

2.10 The second time of hot-pressing

This second hot press takes less time than the first time, only 2-3 minutes because this step aims to stick the face veneer on the board.

2.11 Cutting to size

The panels will be cut into the standard size as per customer's request. The popular sizes of commercial plywood are 1220x2440mm, 910x1820mm,….

2.12 Inspection

After cutting, the goods will be inspected by our experienced QC team one by one to assure all the cargo will be qualified and satisfy the customers. Standard commercial plywood evaluation criteria:

Our TTP is confident of being one of the only units, which has a 100% commercial plywood piece by piece inspection process before stuffing from professional and highly experienced QC teams with the aim of bringing the best Vietnamese plywood products and value to customers.

2.13 Edge treatment

We bathe the edge of the board, which helps to erase the imperfections on the edges and make the edge smooth, flat and beautiful.

2.14 Packaging

Finally, we count and stack up pieces to create a bundle. Four corners of bundles are covered with cartons, tied with strong steel straps, put on the high pallet to make the base which protects the product during the shipping process by sea.

2.15 Loading

These packages will be stored in a spacious and dry warehouse and ready to be loaded into containers for delivery to customers.

Application of Commercical Plywood

- Packing: Commercial Plywood is normally used to pack goods such as electronic components, equipment of machine and high value products to ensure safety during whole tranportation process

- Furniture: Commercial Plywood is widely used to furniture manufacturing imdustry. It can be used to make loft floor, produce furniture such as tables, chairs, doors, cabinets… and many more application

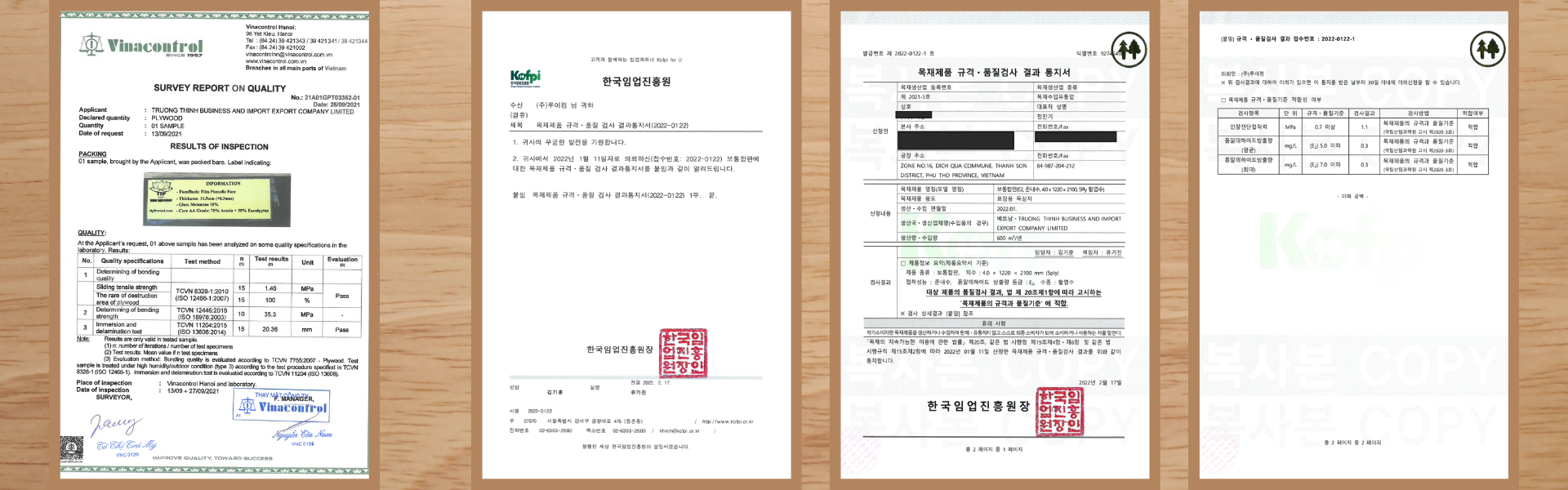

OUR QUALITY CERTIFICATION

During over 10 years in plywood industry, our company always try to serve our customer with most suitable and qualified products. Here are some certificates that indicate the specifications and quality of our plywood, which has been exported to the US, India, Korea, Malaysia, Japan, etc.

------------------------------------------

Hotline/WhatsApp/Line/Kakao: +84 326 942 288

Email: info@ttplywood.com

Website: https://ttplywood.com/

Nationwide delivery

Into money: