-

-

-

Total payment:

-

Packing Plywood - Definition and introductions

Definitions

Packing plywood is the most simpliest and cheapest plywood, made from multiple layers of core veneers, covered with face veneers, which are hot press one times.

Packing plywood are used mostly fot the packaging purposes, it is also the reason why it has this name.

General Information

| Size | 1220x2440mm, 910x1820mm |

| Common Thickness |

7 mm - 4 layers 8 mm - 5 layers 11 mm - 7 layers 14 mm - 9 layers 17 mm - 11 layers |

| Tolerance | +/-0.3 / No minus |

| Core Grade | A/B/C grade core veneer depending on using purpose |

| Application | Box, crate, pallet |

| Glue | urea formaldyhe |

| Formaldehyde Emission | E0/E1/E2 |

| Face | Bintangor 0.13-0.15mm |

| Back | Styrax 0.35-0.4mm |

| Color | Red face and white back |

| Wood species | Acacia, Styrax |

| Technical Info |

1 time hot press No sanding |

| Density | 550-580kgs/m3 |

| Moisture Content | Below 15% |

|

Manufacturer |

TT PLYWOOD |

Characteristics and features of packing plywood

Materials:

Packing plywood are mainly made from hardwood and soft wood mixed together, for example acacia and styrax - Vietnamese-originated woods.

These core veneers are bonded by glue (urea formaldehyde mix with flour, becoming a liquid).

Characteristics

With packing plywood, the grade of appearance is not very important. Instead, customer focus on the strength and price of them.

Packing plywood sheet, should be strong enough so that it can bear the weight of products that put above it. Also, it also need the good bonding so that when cusomer cut them into smaller size, they will not delaminate.

Without sanding, the surface of packing plywood sheet will not be totally even. There will be some rough area in the plywood sheet, but the average will be within the tolerance.

Applications of Packing Plywood

Packing plywood are mainly used for the packaging purposed, they are the common and popular materials to make:

- Box

- Pallet

- Crates

- Shelves in the warehouse

- Making bobbin for wire storing

Besides, packing plywood could also be used to make cheap funiture like the cheao sofa frame, etc.

Reasons to Choose TTPLYWOOD’s Plywood Products

1. High Quality, Meeting International Standards:

TTPLYWOOD’s plywood products are made from high-quality timber sources and undergo rigorous quality control processes. They meet stringent standards, ensuring safety and sustainability in use.

2. Diverse Product Range:

TTPLYWOOD offers a wide variety of plywood products, including film-faced plywood, commercial plywood, LVL, birch core plywood, melamine-coated plywood, and more, suited for various applications in construction, interior design, and packaging.

3. Superior Durability:

TTPLYWOOD plywood stands out for its excellent strength, resistance to warping, and high durability, making it ideal for challenging environments and the climate conditions of Vietnam.

4. Competitive Pricing:

We are committed to delivering high-quality products at reasonable prices. With TTPLYWOOD, customers receive not only a superior product but also optimal cost-efficiency.

5. Attentive After-Sales Service:

TTPLYWOOD is always ready to support customers throughout the product’s usage, with clear warranty policies and flexible return procedures for any issues that may arise.

6. Reliability and Reputation:

TTPLYWOOD is a trusted brand in the plywood market, collaborating with major partners domestically and internationally. We consistently receive positive feedback from our customers for our product quality and dedicated service.

7. Environmental Commitment:

TTPLYWOOD is committed to environmental protection, optimizing production processes to minimize negative impacts on ecosystems.

8. Global Shipping:

With an extensive logistics network, TTPLYWOOD can deliver products to any country, meeting the needs of clients worldwide.

9. Custom Cutting Service:

For added convenience, TTPLYWOOD offers custom-cut plywood services to accommodate specific dimensions as requested, helping save time and costs for projects.

With these strengths, TTPLYWOOD confidently stands as the top choice for quality plywood products, effectively meeting the needs of all customers in construction and interior design.

Production Process

Production Images at TTPLYWOOD

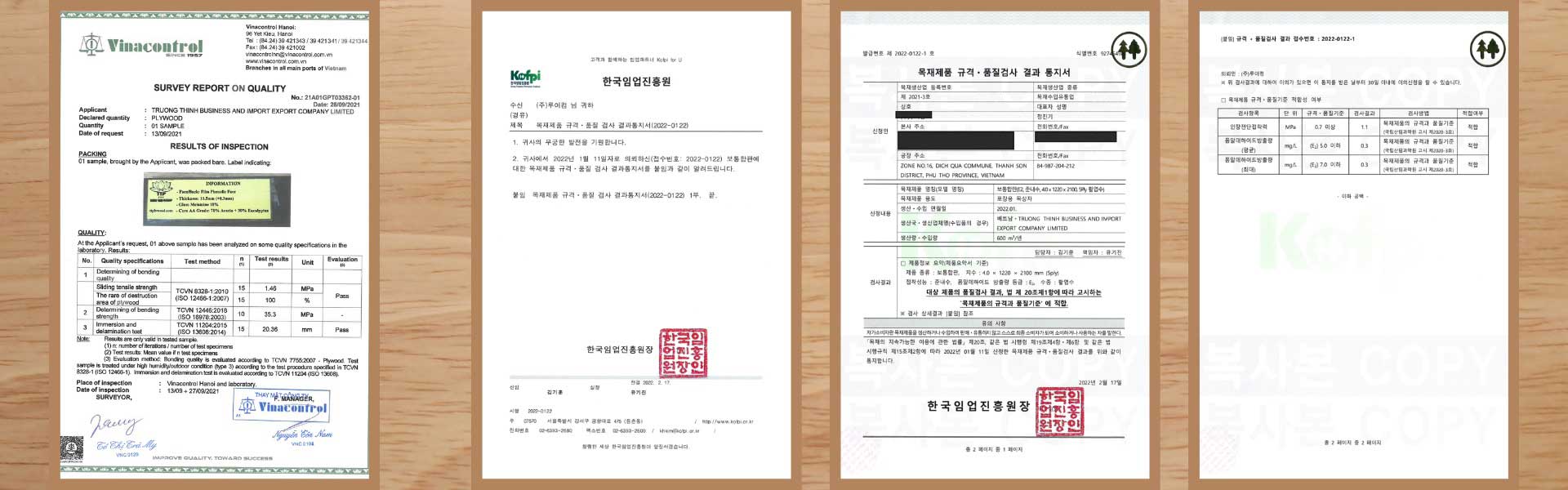

Quality Certifications

During over 10 years in plywood industry, our company always try to serve our customer with most suitable and qualified products. Here are some certificates that indicate the specifications and quality of our plywood, which has been exported to the US, India, Korea, Malaysia, Japan, etc.

See some products

_______________________

Manufacturer and Trading

TRUONG THINH IMPORT EXPORT AND TRADING BUSINESS JOINT STOCK COMPANY

- Office: No LK C34, Hoang Minh Thao Street, Xuan Tao Ward, Bac Tu Liem District, Ha Noi City, Viet nam

- Southern Branch: SAV.1- 02.12 The Sun Avenue building - 28 Mai Chi Tho, An Phu Ward, Thu Duc City, HCM city

- Warehouse: Highway 3, Duc Tu , Dong Anh, Hanoi

- Factory: Area 16, Dich Qua Commune, Thanh Son District, Phu Tho Province

- Hotline/WhatsApp/Line/Kakao: +84 326 942 288

- Email: info@ttplywood.com

- Website: www.ttplywood.com

- Page FB: https://www.facebook.com/ttplywood

- Alibaba: https://ttplywood.trustpass.alibaba.com