-

-

-

Total payment:

-

What is Core plywood?

Core plywood is a construction and furniture material made from thin layers of wood (veneer) stacked and pressed together with glue under high pressure and temperature. This combination provides the product with exceptional durability and strong load-bearing capacity, meeting various usage needs across different industries.

General Information

|

Dimension |

1220 x 2440, 910x1820 mm... |

|

Thickness |

2.5-30mm |

|

Tolerance |

+/- 0.3-0.5mm |

|

Core |

Eucalyptus, acacia |

|

Face |

No |

|

Glue |

E0, E1, E2 |

|

Moisture content |

Below 18% |

|

Density |

560-650kg/m3 |

|

Application |

Making boxes, furniture, construction.... |

Outstanding Features

- High durability: Core plywood possesses excellent load-bearing capacity due to the multiple layers of wood stacked together. This helps the product endure heavy loads without deformation or cracking.

- Moisture and termite resistance: Core plywood is often specially treated to resist termite infestation and moisture, enhancing the product’s longevity in harsh environments.

- Easy to process: Core plywood can be easily cut, drilled, and shaped as needed, making it convenient for designing and constructing furniture or building structures.

- High stability: Thanks to its multi-layered structure, core plywood is less prone to warping or deforming under changing weather conditions, ensuring long-term stability.

Applications

- In construction: Core plywood is widely used in construction projects, especially in formwork systems, molds, and structural components requiring strength and durability.

- In furniture production: The product is often used to make tables, chairs, cabinets, shelves, and many other furniture items due to its ease of processing and high aesthetic value.

- Other applications: In addition, core plywood is also used for producing flooring, wall cladding, ceilings, and many other decorative interior applications.

Reasons to Choose Core Plywood Of TT PLYWOOD

- Superior durability: The product can withstand heavy loads and harsh environments, ensuring long-lasting life.

- Cost-effective: Compared to solid natural wood, core plywood is more affordable while still ensuring quality.

- Easy to construct and install: Thanks to its flexibility in processing, core plywood helps reduce construction time and costs.

TT PLYWOOD Core Plywood Production Process

CORE PLYWOOD PRODUCTION VIDEO

CORE PLYWOOD PRODUCTION DETAILS

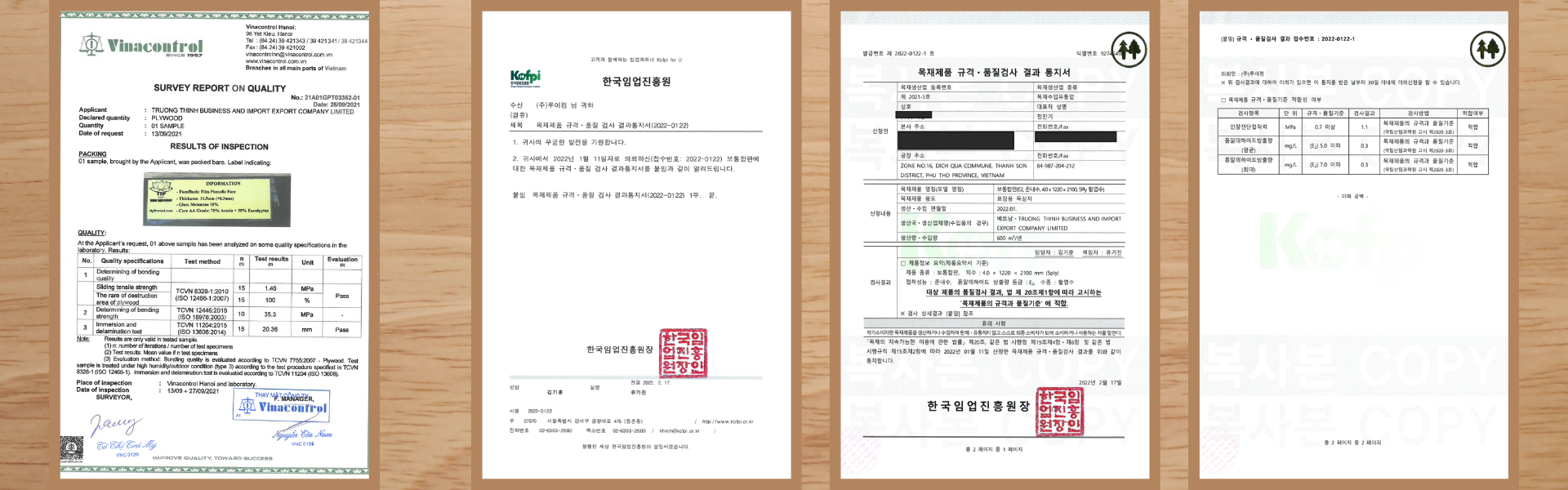

Our quality certification

During over 10 years in plywood industry, our company always try to serve our customer with most suitable and qualified products. Here are some certificates that indicate the specifications and quality of our plywood, which has been exported to the US, India, Korea, Malaysia, Japan, etc.

See some products

_______________________

Manufacturer and Trading

TRUONG THINH IMPORT EXPORT AND TRADING BUSINESS JOINT STOCK COMPANY

- Office: No LK C34, Hoang Minh Thao Street, Xuan Tao Ward, Bac Tu Liem District, Ha Noi City, Viet nam

- Southern Branch: SAV.1- 02.12 The Sun Avenue building - 28 Mai Chi Tho, An Phu Ward, Thu Duc City, HCM city

- Warehouse: Highway 3, Duc Tu , Dong Anh, Hanoi

- Factory: Area 16, Dich Qua Commune, Thanh Son District, Phu Tho Province

- Hotline/WhatsApp/Line/Kakao: +84 326 942 288

- Email: info@ttplywood.com

- Website: www.ttplywood.com

- Page FB: https://www.facebook.com/ttplywood

- Alibaba: https://ttplywood.trustpass.alibaba.com