-

-

-

Total payment:

-

Birch Plywood - Definition and introductions

Definitions

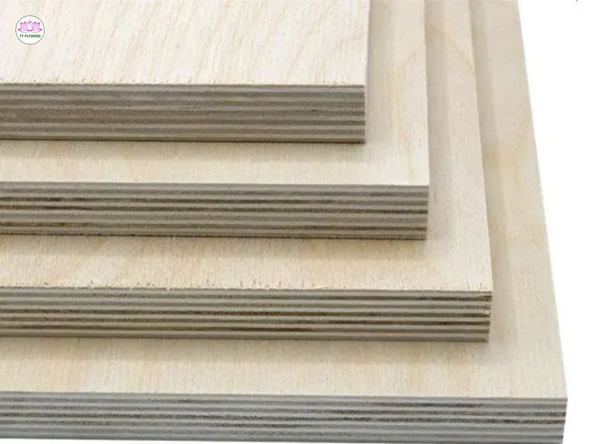

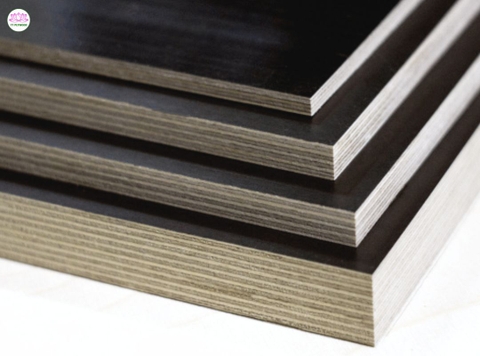

Birch plywood is a product with high perfomance and high aesthetic, suitable for interior funiture applications. They are characterized by two sides face and back made of birch veneers, a beautiful and high quality wood.

Material Composition and Technical Details

- Core Options: 100% eucalyptus or mixed eucalyptus-acacia hardwood for improved stability and screw-holding capacity

- Face and Back Veneer: Natural birch veneer with consistent grain and smooth appearance

- Adhesive Options: E0, E1, or E2 glue systems compliant with CARB Phase 2 and EU formaldehyde emission standards

- Processing: Double-sided sanding for precise thickness and an even, smooth finish

Key Features

- Aesthetic Appeal: Light color and uniform grain make it ideal for visible surfaces, Scandinavian-style interiors, and high-end furniture.

- Structural Integrity: Multi-layer hardwood core (7 to 13 plies depending on thickness) provides excellent load-bearing strength and dimensional stability.

- Precision Manufacturing: Each sheet is calibrated with tight tolerance, ensuring suitability for CNC routing and precision joinery.

- Consistency and Quality Assurance: All panels are inspected individually prior to shipment to ensure minimal defect rate.

Typical Applications

- Interior and exterior furniture components

- Cabinetry and wardrobe production

- Wooden toys and educational materials

- Interior wall cladding, partitions, and doors

- Flooring base and subflooring systems

Advantages of TT Plywood Birch Panels

- Full control over sourcing and production ensures competitive pricing without compromising quality

- All shipments are packed securely for international transport, minimizing handling damage

- Ability to customize thickness, size, surface grade, and adhesive type to meet buyer specifications

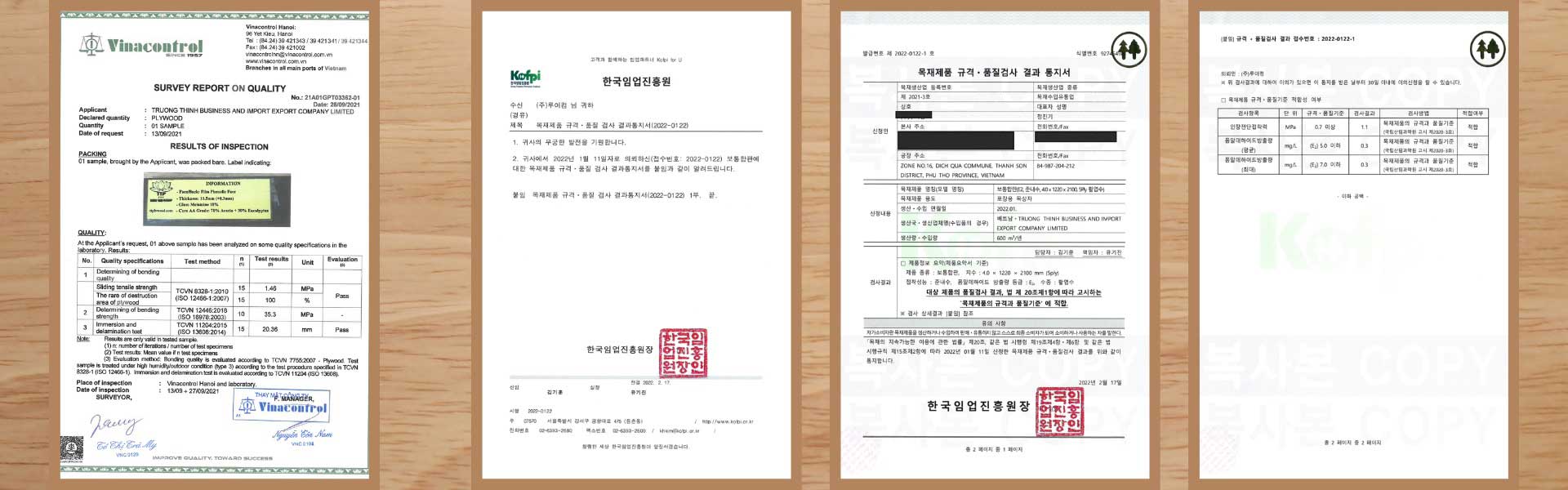

- Technical documentation and third-party certifications (FSC®, CARB, EN13986) available upon request

Production Process

Quality Certifications

During over 10 years in plywood industry, our company always try to serve our customer with most suitable and qualified products. Here are some certificates that indicate the specifications and quality of our plywood, which has been exported to the US, India, Korea, Malaysia, Japan, etc.

__________________________________

Manufacturer and Trading

TRUONG THINH IMPORT EXPORT AND TRADING BUSINESS JOINT STOCK COMPANY

- Office: No LK C34, Hoang Minh Thao Street, Xuan Tao Ward, Bac Tu Liem District, Ha Noi City, Viet nam

- Southern Branch: SAV.1- 02.12 The Sun Avenue building - 28 Mai Chi Tho, An Phu Ward, Thu Duc City, HCM city

- Warehouse: Highway 3, Duc Tu , Dong Anh, Hanoi

- Factory: Area 16, Dich Qua Commune, Thanh Son District, Phu Tho Province

- Hotline/WhatsApp/Line/Kakao: +84 326 942 288

- Email: info@ttplywood.com

- Website: www.ttplywood.com

- Page FB: https://www.facebook.com/ttplywood

- Alibaba: https://ttplywood.trustpass.alibaba.com