-

-

-

Total payment:

-

Plywood vs OSB: Which Subfloor Material Lasts Longer?

Posted by Thanh Uyên at 12/08/2025

Selecting the right subfloor material is more than a construction detail — it’s an investment in the long-term comfort, durability, and safety of a building. For decades, two contenders have dominated the market: plywood and OSB (Oriented Strand Board). Each has its loyal supporters and its list of trade-offs, and knowing which one will last longer depends on understanding their properties, how they respond to environmental challenges, and how they perform under different flooring types.

This guide explores their differences in moisture resistance, strength, fastening, cost, and compatibility with finished flooring. By the end, you’ll have the information needed to make a confident choice for your project.

How They Are Made

Plywood is manufactured by bonding thin sheets of wood veneer together, with each layer’s grain direction alternating at 90 degrees to the one beneath it. This cross-lamination gives plywood its excellent tensile strength, resistance to splitting, and dimensional stability. OSB is produced by arranging large, thin wood strands in layers, bonding them with resin, and compressing the panel under heat and pressure to create a consistent, dense sheet.

Plywood is made by bonding multiple thin wood veneer layers together, with each layer’s grain running perpendicular to the previous one. This cross-laminated construction gives plywood high strength, dimensional stability, and better resistance to warping. In the US, subfloor-grade plywood is typically APA-rated, while in the EU, EN 636 standards apply. Common subfloor thicknesses range from 15–19 mm (5/8–3/4"). For a detailed breakdown of recommended thicknesses for different flooring systems, check our Ultimate Guide to Plywood Thickness for Subfloors.

The difference in structure is critical: plywood’s layered veneer pattern gives it better recovery from swelling and shrinkage, while OSB’s uniform composition enhances its stiffness and load distribution.

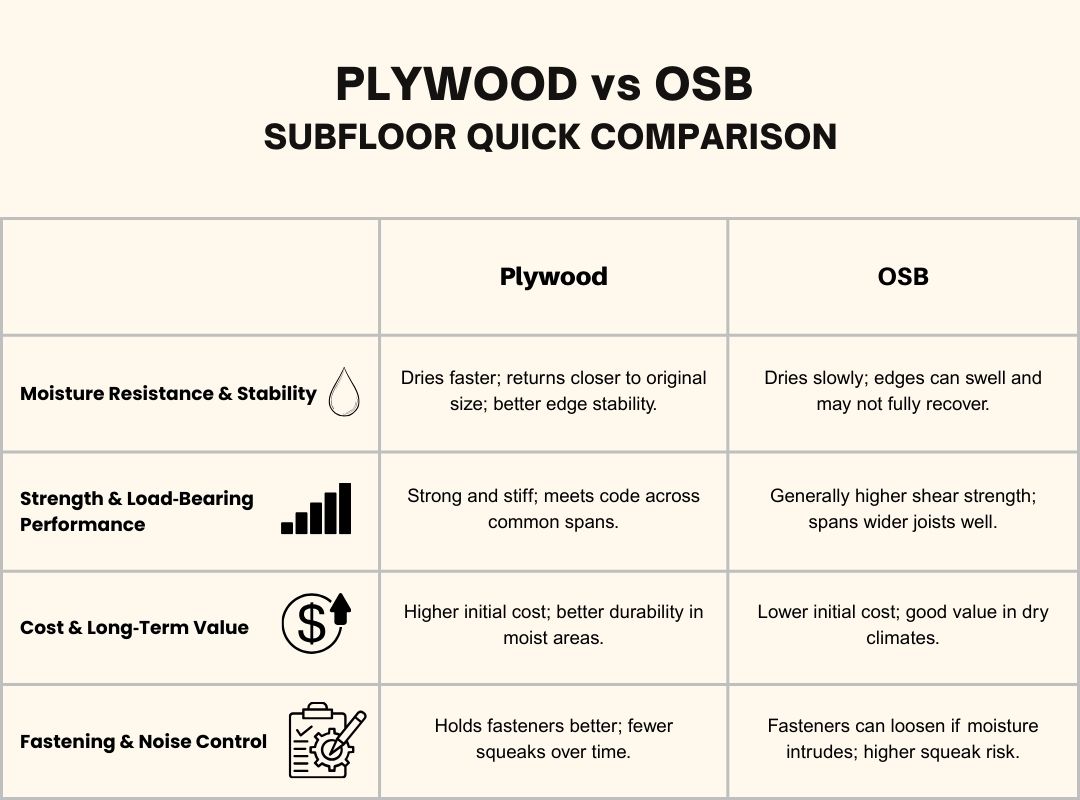

Moisture Resistance and Stability

Moisture is one of the most significant threats to any subfloor. Plywood generally handles water exposure better. It dries faster than OSB and tends to return close to its original dimensions after drying. OSB absorbs water more slowly, but once moisture penetrates, it takes much longer to dry and often swells at the edges swelling that may never fully recede.

For kitchens, bathrooms, basements, or any area where spills or leaks are possible, plywood’s quick-drying nature is an advantage. In contrast, OSB performs well in dry climates where prolonged moisture exposure is unlikely.

Strength and Load-Bearing Performance

Both plywood and OSB are engineered to meet building code requirements for subfloors, but OSB generally boasts a higher shear strength often around twice that of plywood. This means it can resist racking forces and provide impressive stiffness across wider joist spacing.

Contractors often notice OSB panels feel slightly more rigid during installation, particularly when spanning large distances. However, in everyday residential use, especially with standard joist spacing and finished flooring in place, the difference in feel may be minimal.

Cost and Long-Term Value

Price is a decisive factor for many builders and homeowners. OSB tends to cost less, sometimes significantly, especially in thicker panels. For large projects, these savings can add up to hundreds or thousands of dollars.

However, plywood’s superior moisture resistance can translate into fewer repairs and replacements over time. While the upfront cost is higher, the total life-cycle cost may be lower if it avoids swelling, squeaking, or structural issues that require intervention.

Fastening and Noise Control

Fastener retention is a critical, yet often overlooked, element of subfloor performance. Plywood’s veneer layers grip nails and screws more securely, reducing the risk of movement and floor squeaks over time. This makes it a preferred choice in multi-story homes or areas with heavy foot traffic.

OSB can hold fasteners well when dry, but if exposed to moisture, the bond weakens more quickly. Over time, this can lead to loosening fasteners, floor movement, and unwanted noise.

Key Advantages of Plywood

- Dries faster after moisture exposure and returns close to its original dimensions.

- Holds screws and nails more securely, preventing movement and squeaks.

- Ideal for tile and stone installations due to higher stiffness.

- Maintains integrity longer in humid or damp conditions.

Key Advantages of OSB

- Offers higher shear strength, providing excellent rigidity.

- Lower cost makes it appealing for budget-conscious projects.

- Uniform size and density make installation predictable and straightforward.

- Performs well in dry climates where moisture risks are minimal.

Compatibility with Different Flooring Types

For tile and stone, plywood is the safer bet because it provides the necessary stiffness to prevent cracks in brittle surfaces. OSB can be used for tile installations only if paired with a solid cement board or an uncoupling membrane, which adds complexity and cost.

For laminate, vinyl, or engineered wood, both materials can work well as long as they are kept dry and installed correctly. In these cases, the choice often comes down to budget and local availability.

Plywood vs OSB: Side-by-Side Comparison

| Feature / Property | Plywood | OSB |

|---|---|---|

| Moisture Resistance | Excellent recovery after wetting | Slower drying; edge swelling may remain |

| Shear Strength | Strong, but lower than OSB | Approximately twice the shear strength |

| Fastener Holding | Superior grip for screws/nails | Weakens if exposed to moisture |

| Cost | More expensive | Lower cost, better for large projects |

| Tile/Stone Suitability | Highly suitable without extra layers | Requires cement board or uncoupling mat |

| Installation | May chip on edges, slightly less uniform | Consistent, easy to cut and handle |

| Weight | Lighter | Heavier |

When to Choose Each

Plywood is best for high-moisture areas, upper floors that need sound control, and projects where tile or stone will be installed. OSB is a good fit for large, dry-climate builds where cost savings and panel stiffness are the main priorities. In both cases, proper installation, adequate fastener spacing, and following manufacturer recommendations will ensure the subfloor performs as intended.

Conclusion

The plywood vs OSB debate doesn’t have a one-size-fits-all answer. Plywood shines in moisture management and fastener retention, while OSB delivers cost efficiency and impressive stiffness. The best choice depends on climate, budget, flooring type, and the builder’s long-term performance expectations. By weighing these factors carefully, you can create a subfloor that not only meets code but delivers comfort, stability, and durability for years to come.

Choosing between plywood and OSB is not just about meeting building codes — it’s about ensuring your floor remains strong, stable, and silent for decades. If you’re still unsure which material fits your project best, our team at TT Plywood is here to help.

Hotline/WhatsApp/Line/Kakao: +84 32 694 2288

Email: info@ttplywood.com

Website: ttplywood.com

👉 Get a free consultation and material quote today — let us help you build a subfloor that lasts.

Frequently Asked Questions (FAQ)

Q1: Which lasts longer plywood or OSB in a subfloor?

A1: In most residential environments, plywood tends to last longer, especially in areas exposed to moisture. While OSB offers impressive stiffness and is often more affordable, it can be more susceptible to swelling at the edges when wet. For projects where long-term durability and moisture resistance are priorities, plywood is generally the better choice.

Q2: Can OSB be used under tile flooring?

A2: OSB can be used under tile, but it requires an additional rigid underlayment such as cement board or an uncoupling membrane to prevent cracking. Plywood, on the other hand, can support tile installations without as many additional layers. For more details on subfloor preparation for tile, see our guide on Plywood Thickness for Subfloors.

Q3: What thickness should I use for a subfloor?

A3: Thickness depends on joist spacing and flooring type. For standard 16" joist spacing, 19 mm (3/4") plywood is often recommended for added stability. Wider joist spacing or heavy flooring like tile may require double-layer construction. You can find a detailed breakdown in our Ultimate Guide to Plywood Thickness for Subfloors.