-

-

-

Total payment:

-

The Hidden Costs of Cheap Plywood: How to Avoid Quality Claims in International Trade

Posted by Thanh Uyên at 10/09/2025

At first glance, cheap plywood may seem like a smart business decision especially in international trade where price often dominates negotiations. Yet, importers across Europe and North America are increasingly realizing that what looks like a bargain upfront can quickly spiral into costly disputes, rejected shipments, and damaged reputations.

In this article, we uncover the hidden costs of low-quality plywood, explain why quality claims are rising in global trade, and offer a roadmap for avoiding these pitfalls. With global demand for plywood projected to exceed $100 billion by 2032 (Coherent Market Insights, 2024), buyers cannot afford to cut corners on quality.

The Real Price of Cheap Plywood

The plywood market is highly competitive, and some suppliers reduce prices by compromising on raw material, glue type, or production standards. While the invoice total may look attractive, the “savings” are often outweighed by downstream costs.

The most common hidden costs include:

- Claims and Replacements: Importers face expensive disputes if panels fail to meet contract specifications.

- Project Delays: Construction or furniture production may be halted when substandard boards cannot be used.

- Regulatory Fines: Non-compliance with EU or US standards (FSC, CARB, CE) can trigger penalties.

- Brand Damage: A single faulty shipment can undermine years of trust with clients.

Common Triggers for Quality Claims

In international plywood trade, claims often arise from the following issues:

- Inconsistent Thickness: Panels outside tolerance create problems in construction or furniture fitting.

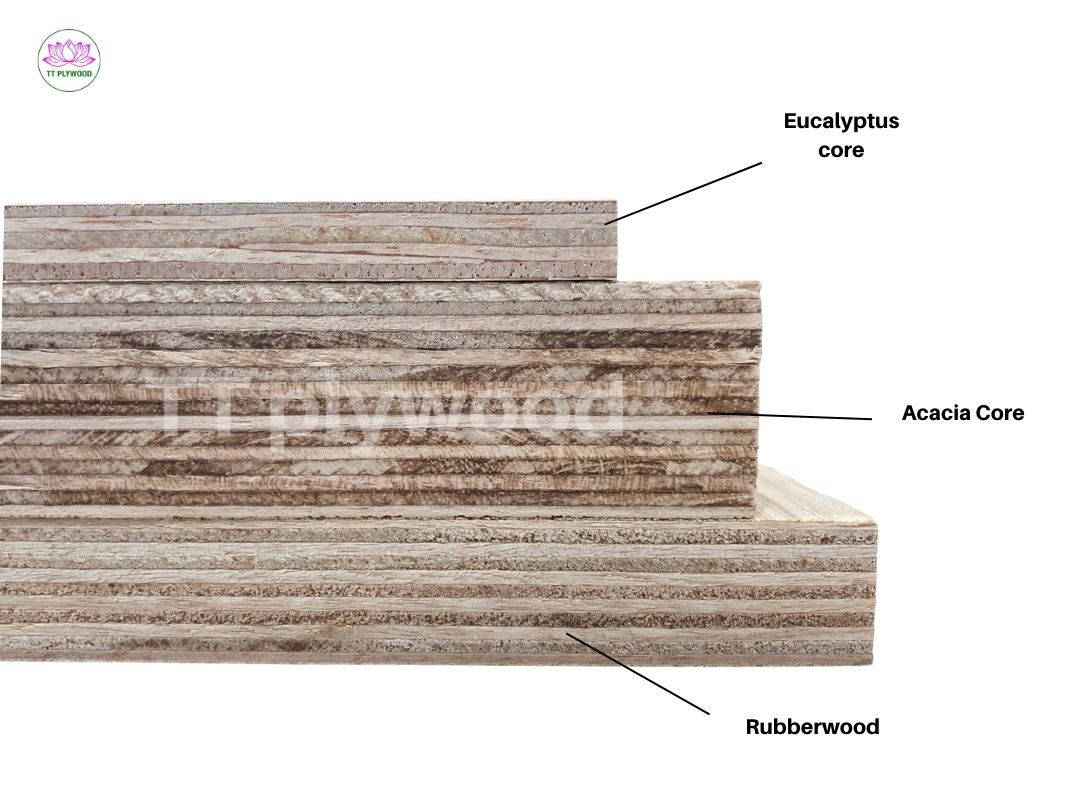

- Core Gaps and Voids: Poorly manufactured cores reduce strength and stability.

- Delamination: Low-quality adhesives fail under humidity or stress.

- Surface Defects: Knots, patches, or rough finishing make plywood unsuitable for visible applications.

- Non-compliance Certificates: Missing or fake FSC/CE documentation exposes buyers to legal risks.

Case in Point: EU and US Buyers on Alert

Both European and US markets are tightening quality controls. The EU requires plywood imports to meet EUDR-ready standards and CE certification, while the US enforces strict CARB/EPA emissions rules. Recent industry reports note a rise in shipments being rejected at ports due to formaldehyde levels, misdeclared origin, or thickness variations (European Commission, 2023; US EPA, 2024).

How to Avoid Quality Claims

The good news is that importers can minimize risks by adopting stronger procurement strategies.

1. Source from Trusted Manufacturers

Suppliers with proven track records and transparent production facilities reduce the chance of defects. Site audits or virtual inspections help verify quality control.

2. Demand Clear Specifications

Contracts should include veneer type, glue, thickness tolerance, and grade. Vague agreements create loopholes for disputes.

3. Verify Certifications

Always cross-check FSC, CE, or CARB certificates in public databases. Fake documentation is increasingly common in the global timber trade.

4. Inspect Shipments Regularly

Random sampling and third-party inspections protect against hidden defects before cargo leaves port.

5. Balance Price and Performance

The lowest price rarely delivers the best long-term value. Premium panels can reduce waste, rework, and claims.

Lessons for European Importers

For many European buyers, the temptation of low-cost panels from non-traditional sources has grown since sanctions restricted imports of Russian birch plywood. But the reality is that this strategy often results in more problems than savings. Germany, Spain, and the Netherlands have all reported cases of shipments being rejected at port inspections for failing to meet CE standards or for carrying incomplete documentation (European Commission, 2023).

The hidden cost is not just the replacement of faulty material. A rejected load can mean:

- Delays in project schedules for construction firms, which rely on “just-in-time” deliveries.

- Financial penalties when subcontractors cannot complete milestones.

- Reputational risk when contractors associate the importer’s brand with unreliability.

European importers have learned that mitigating these risks means prioritizing suppliers with transparent production lines and documented traceability. That is why Vietnamese birch plywood is increasingly seen as a safer alternative to Baltic or Chinese low-cost substitutes. Vietnam offers competitive pricing but also the certifications FSC, EUDR-ready, and CE-marked panels needed to move smoothly through EU customs.

👉 For a deeper comparison, see our article: Vietnamese Birch Plywood — The Best Alternative to Baltic Birch.

Lessons for Packaging and Core Buyers

Sweden and the Nordic region illustrate another angle of the quality issue. Here, the demand is less about surface appearance and more about strength, stability, and cost-effectiveness in packaging. Core plywood that cracks under heavy load or fails in humid shipping conditions creates enormous liabilities.

One Swedish logistics firm recently highlighted that pallet failures not only damaged goods but also disrupted entire shipping schedules across Europe’s largest ports (Swedish Wood, 2023). These indirect costs lost goods, insurance claims, and contract disputes—can easily outweigh the small savings made on cheaper boards.

Buyers in this segment are learning that:

- Consistent density and bonding are non-negotiable for packaging panels.

- Verified thickness tolerance prevents pallet collapse and uneven weight distribution.

- Pressure-tested core plywood with strong adhesive bonds significantly reduces claim risks.

TT Plywood’s shipments of core plywood for crates and pallets are designed to meet exactly these requirements. With thickness tolerances tightly controlled and certification packages prepared for customs clearance, our panels help Swedish buyers cut liability risks and ensure cargo safety.

👉 To understand why thickness and structure matter in performance, check our Ultimate Guide to Plywood Thickness for Subfloors.

The Cost-Benefit Equation

When evaluating plywood suppliers, importers should look beyond the invoice. Consider the full equation:

- Initial Price vs. Replacement Costs

- Supplier Transparency vs. Claim Risks

- Certification Compliance vs. Customs Delays

- Premium Quality vs. Brand Reputation

By calculating Total Cost of Ownership (TCO) rather than unit cost alone, buyers often find that premium plywood offers greater savings over time.

Cheap plywood may reduce purchase price but increases the risk of claims, disputes, and reputational harm. For European and US buyers, avoiding these hidden costs requires partnering with trusted suppliers, demanding strict specifications, and prioritizing compliance.

At TT Plywood, we deliver:

- Premium birch plywood for furniture and interiors.

- Reliable core plywood for packaging and logistics.

- Full FSC, CE, and EUDR-ready documentation.

- Proven on-time delivery to EU and US markets.

📩 Contact us today at info@ttplywood.com to secure high-quality, claim-free plywood for your next project.

FAQ

Q1: What are the most common quality issues with cheap plywood?

Inconsistent thickness, delamination, surface defects, and missing certificates are frequent triggers for claims.

Q2: How can importers verify plywood certifications?

Check FSC, CE, or CARB codes in official databases and request the latest audit reports from suppliers.

Q3: Why is thickness tolerance so important?

Panels outside tolerance disrupt construction or furniture assembly, leading to costly delays.

Q4: Are Vietnamese plywood exports accepted in EU and US markets?

Yes. With proper certification (FSC, CARB, EUDR-ready), Vietnamese plywood is increasingly recognized as a reliable source.

Q5: How do I balance cost with quality?

Compare not only unit prices but also potential costs of claims, delays, and brand damage. Premium quality often provides better value.

References

- Coherent Market Insights (2024). Plywood Market Report 2024–2032. Available at: https://www.coherentmarketinsights.com/market-insight/plywood-market-2212 [Accessed 10 Sep. 2025].

- European Commission (2023). Regulation on deforestation-free products. Available at: https://environment.ec.europa.eu/topics/forests/deforestation/regulation-deforestation-free-products_en [Accessed 10 Sep. 2025].

- US Environmental Protection Agency (2024). Formaldehyde Emission Standards for Composite Wood Products. Available at: https://www.epa.gov/formaldehyde/formaldehyde-emission-standards-composite-wood-products [Accessed 10 Sep. 2025].

- Swedish Wood (2023). Wood packaging and climate benefits. Available at: https://www.swedishwood.com/sustainability/climate-benefit/wood-packaging [Accessed 10 Sep. 2025].