-

-

-

Total payment:

-

Why Vietnamese LVL Can Replace Solid Wood for Furniture Frames

Posted by Thanh Uyên at 23/04/2025

For decades, solid wood has been the preferred choice for furniture frames. However, its limitations—high cost, susceptibility to warping, and inconsistent quality—have led manufacturers to seek better alternatives. Vietnamese LVL (Laminated Veneer Lumber) has emerged as a superior solution, offering enhanced strength, stability, and cost-efficiency while supporting sustainable production.

This article explores:

- What LVL is and how it's manufactured

- Key advantages over traditional solid wood

- Why Vietnam is a leading LVL supplier

- Best applications in furniture production

1. Understanding LVL: A Modern Wood Engineering Solution

LVL is an engineered wood product created by bonding thin wood veneers under controlled heat and pressure. Unlike solid wood, which contains natural imperfections, LVL delivers uniform strength and dimensional stability.

Manufacturing Process of Vietnamese LVL:

- Log Selection: Sustainably sourced hardwood (eucalyptus, acacia, or rubberwood)

- Veneer Peeling: Rotary-cut into 1-3mm thick sheets

- Drying: Moisture content reduced to 8-12% for stability

- Layering & Gluing: Veneers stacked with grain parallel for maximum strength

- Hot Pressing: Bonded under high pressure (150-200 kg/cm²) at 120-150°C

This engineered approach eliminates the weaknesses found in natural wood while enhancing structural performance.

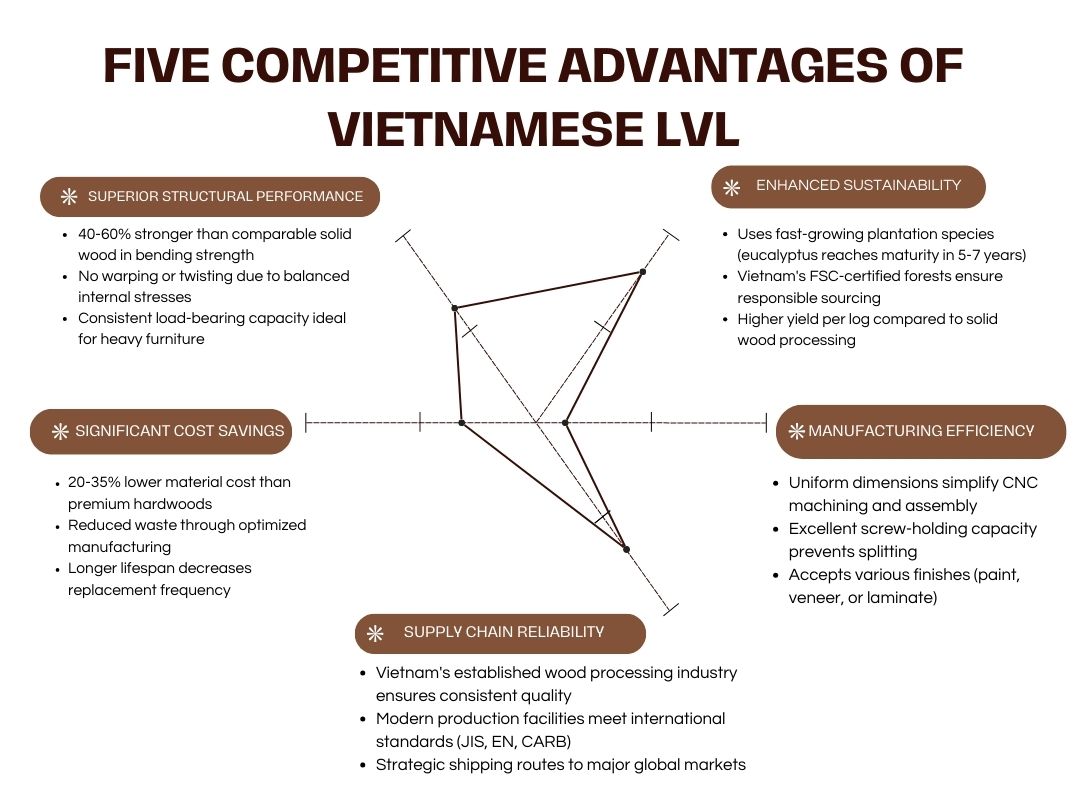

2. Five Competitive Advantages of Vietnamese LVL

1. Superior Structural Performance

- 40-60% stronger than comparable solid wood in bending strength

- No warping or twisting due to balanced internal stresses

- Consistent load-bearing capacity ideal for heavy furniture

2. Significant Cost Savings

- 20-35% lower material cost than premium hardwoods

- Reduced waste through optimized manufacturing

- Longer lifespan decreases replacement frequency

3. Enhanced Sustainability

- Uses fast-growing plantation species (eucalyptus reaches maturity in 5-7 years)

- Vietnam's FSC-certified forests ensure responsible sourcing

- Higher yield per log compared to solid wood processing

4. Manufacturing Efficiency

- Uniform dimensions simplify CNC machining and assembly

- Excellent screw-holding capacity prevents splitting

- Accepts various finishes (paint, veneer, or laminate)

5. Supply Chain Reliability

- Vietnam's established wood processing industry ensures consistent quality

- Modern production facilities meet international standards (JIS, EN, CARB)

- Strategic shipping routes to major global markets

3. Vietnam's Competitive Edge in LVL Production

Vietnam has become a preferred LVL supplier due to:

- Abundant raw materials: 4.4 million hectares of production forests

- Advanced manufacturing technology: Japanese and European equipment

- Cost competitiveness: Lower production costs than China or Europe

- Quality certifications: FSC, PEFC, and CE compliant production

"Over 60% of LVL imported by Japanese furniture manufacturers now originates from Vietnam."

4. Optimal Applications in Furniture Manufacturing

- Bedroom Furniture: Headboards and bed frames benefit from LVL's resistance to sagging

- Dining Sets: Table bases and chair frames maintain stability in varying humidity

- Case Goods: Cabinet and wardrobe frames provide screw-holding reliability

- Upholstered Furniture: Strong yet lightweight frames reduce shipping costs

5. Addressing Common Industry Concerns

Durability Comparison

Independent testing shows LVL maintains structural integrity 2-3 times longer than solid wood in humid conditions.

Aesthetic Flexibility

LVL substrates readily accept:

- Real wood veneers for premium finishes

- High-pressure laminates for contemporary styles

- Paint coatings for uniform appearance

Environmental Impact

Vietnamese LVL production:

- Uses 30% less raw material than solid wood equivalents

- Generates 50% less production waste

- Features formaldehyde-free adhesive options

6. Sourcing High-Quality Vietnamese LVL

Key specifications to request:

|

Parameter |

Premium Grade |

Standard Grade |

|

Wood Species |

Eucalyptus/Acacia |

Mixed Hardwood |

|

Density |

≥700kg/m³ |

650-700kg/m³ |

|

Moisture Content |

8-10% |

10-12% |

|

Formaldehyde |

E0 (<0.5ppm) |

E1 (0.5-1.5ppm) |

|

Certifications |

FSC, CARB |

CE, PEFC |

Download Our LVL Technical Specifications

7. Conclusion: The Future of Furniture Framing

Vietnamese LVL represents the evolution of wood construction materials, offering furniture manufacturers:

- Improved product performance through engineered consistency

- Reduced material costs without sacrificing quality

- Sustainable production aligned with eco-conscious values

Ready to explore LVL for your next production run? Contact our technical team for customized solutions.

📞Hotline/WhatsApp/Line/Kakao: +84 32 694 2288

📧Email: info@ttplywood.com

🌐Website: https://ttplywood.com/

LinkedIn: https://www.linkedin.com/in/tt-plywood/

Frequently Asked Questions

Q: What thicknesses are available for furniture applications?

A: Standard ranges from 18mm to 50mm, with custom sizes available.

Q: How does lead time compare to solid wood procurement?

A: Vietnamese LVL typically ships 30-45 days faster than quality hardwood.

Q: Can LVL be used with existing woodworking equipment?

A: Yes, it machines similarly to hardwood with reduced tool wear.