-

-

-

Total payment:

-

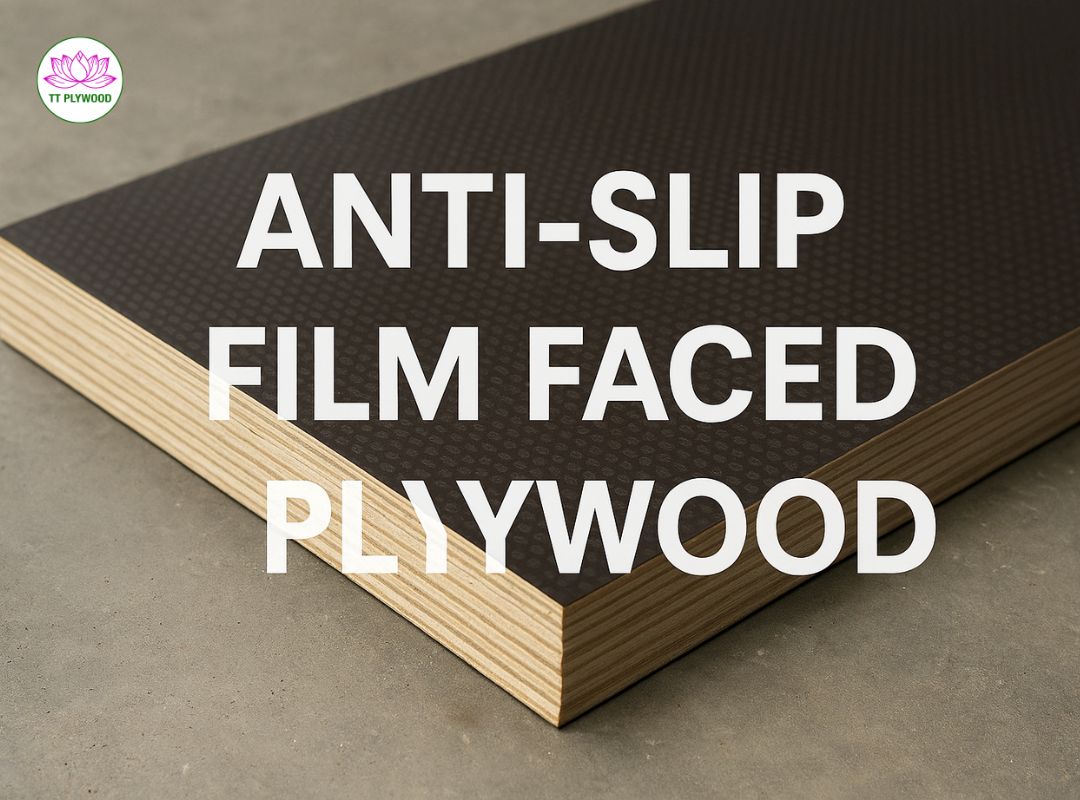

Anti-Slip Film Faced Plywood for Scaffolding & Flooring – Safety & Durability | TT Plywood

Posted by Thanh Uyên at 07/10/2025

When it comes to construction safety, one of the most overlooked yet vital materials is anti-slip film faced plywood. Whether used for scaffolding platforms, temporary flooring, or concrete formwork, this engineered panel ensures stability under tough site conditions. Slips and falls remain one of the most common causes of construction injuries globally, and choosing the right plywood surface can make a major difference.

Film faced plywood, particularly with an anti-slip or “mesh” surface, has become an industry standard for scaffolding and flooring in Europe, the Middle East, and Southeast Asia. Manufacturers such as TT Plywood in Vietnam have refined the technology to combine strength, water resistance, and traction all within a reusable, sustainable panel.

What Is Anti-Slip Film Faced Plywood?

Anti-slip film faced plywood is a high-strength engineered panel coated with a phenolic film overlay on both faces. The top layer features a textured, mesh-like pattern that increases grip, while the bottom surface remains smooth to resist moisture. The core is typically made from hardwood species like eucalyptus, acacia, or birch, bonded with waterproof phenolic or melamine glue.

These panels are pressed under high temperature and pressure, forming a dense and stable board capable of handling heavy loads and outdoor exposure. For scaffolding and flooring, the anti-slip surface minimizes accidents, even in wet or muddy environments.

👉 Learn more: Film Faced Plywood Thickness 21mm 13 Layers.

Key Construction Advantages

The main value of anti-slip plywood lies in its balance between durability, water resistance, and safety performance. Traditional plywood may become slippery when wet, while metal platforms corrode and transfer heat. Anti-slip plywood offers a dependable, cost-effective solution that’s easy to install and replace.

Core advantages include:

- Enhanced traction: The embossed pattern increases grip, reducing slipping risks.

- Water resistance: Phenolic film prevents water absorption and swelling.

- Structural strength: Engineered from multiple veneers bonded with waterproof resin.

- Long lifespan: With proper care, panels can be reused 8–12 times in formwork or platforms.

- Easy cleaning: Smooth underside prevents concrete adhesion and simplifies maintenance.

Applications: Scaffolding, Platforms, and Industrial Flooring

Anti-slip film faced plywood is specifically designed for environments that demand both load-bearing capacity and secure footing. The material’s unique combination of surface texture and resin bonding makes it ideal for a wide range of applications.

Typical use cases include:

- Scaffolding decks and working platforms

- Industrial walkways and warehouse flooring

- Stage and event flooring

- Truck beds and loading docks

- Temporary ramps and outdoor flooring for construction sites

For scaffolding systems, the panels are cut into standard deck sizes (for example 1220 × 2440 mm or custom 1250 × 2500 mm) and fitted into steel or aluminum frames. The anti-slip film ensures safety even when mud, oil, or concrete residues are present.

Material Composition and Core Options

Vietnamese producers like TT Plywood use high-density hardwood veneers sourced from eucalyptus, acacia, or rubberwood plantations. These cores are combined with phenolic WBP glue, achieving bonding strength that meets EN 314-2 Class 3 or BS 1088 standards.

For high-end projects, birch-core anti-slip plywood is often chosen for its uniform density and smooth edges. However, eucalyptus or acacia core plywood offers similar mechanical properties at a lower cost, making it a preferred option in Asia, Australia, and the Middle East.

The top film layer (typically 120–220 g/m²) can be brown, black, or dark grey, depending on user preference and application environment.

Safety Standards and Certifications

Safety on scaffolding depends heavily on panel quality. Reputable suppliers ensure that every batch of anti-slip plywood complies with international standards such as:

- EN 636 / EN 314-2: European structural and bonding strength standards.

- BS 1088: Marine-grade durability classification.

- CARB / EPA TSCA Title VI: Low-formaldehyde emissions for healthier workplaces.

- FSC® Certification: Responsible sourcing from sustainable forests.

Using certified materials ensures consistent performance and aligns with global green-building regulations.

👉 Related reading: Plywood Certifications Explained: FSC, PEFC, CARB/EPA, CE.

Durability Under Harsh Conditions

Anti-slip film faced plywood is built to withstand the toughest construction sites. The phenolic overlay not only repels water but also resists chemicals, abrasion, and UV exposure. The anti-slip texture remains effective even after repeated use.

When compared to traditional film faced plywood, anti-slip variants maintain traction in conditions where smooth panels may fail. Proper edge sealing with waterproof paint further prevents delamination and swelling, extending service life.

For scaffolding and flooring contractors, this translates into fewer replacements, improved safety compliance, and reduced downtime.

Maintenance and Reuse

Proper care significantly extends the lifespan of anti-slip plywood. After each project cycle, panels should be cleaned of concrete residue and stored flat to avoid warping. Edge resealing between uses helps prevent moisture ingress.

Because of their high-density cores and strong phenolic bonding, many TT Plywood clients report reuse cycles exceeding ten times under proper handling. This reusability also enhances sustainability by reducing total material consumption.

Eco-Friendly and Sustainable Features

In addition to safety, anti-slip plywood offers environmental benefits. The use of plantation-grown eucalyptus and acacia reduces dependence on old-growth forests. Factories like TT Plywood also utilize energy-efficient hot-press technology and FSC-certified veneers, ensuring both sustainability and consistent product quality.

Compared to steel decking, plywood requires less energy to produce and transport, resulting in a lower carbon footprint. Its biodegradable nature means that even after end-of-life, panels can be recycled or repurposed into composite materials.

👉 Explore more: Why Vietnamese LVL Can Replace Solid Wood for Furniture Frames.

Why Choose Vietnamese Anti-Slip Plywood?

Vietnam has emerged as a leading producer of film faced plywood for export markets, combining cost efficiency with strict quality standards. TT Plywood’s anti-slip products are tailored for scaffolding, flooring, and formwork contractors who need consistent strength, waterproof bonding, and non-slip performance.

With proximity to key Asian shipping routes and strong compliance with EN, BS, and CARB standards, Vietnam’s plywood products have earned trust across Europe, the U.S., and Australia.

Frequently Asked Questions (FAQ)

1. What makes anti-slip film faced plywood different from regular film faced plywood?

It features a textured top layer for improved grip and safety, while regular film faced plywood has a smooth surface primarily designed for concrete formwork.

2. How long can anti-slip plywood be reused?

Depending on the core and glue type, it can be reused 8–12 times with proper care.

3. Is it waterproof?

It is water-resistant, not fully waterproof. The phenolic coating repels moisture effectively for outdoor and scaffold applications.

4. Can anti-slip plywood be cut to custom sizes?

Yes, TT Plywood provides CNC-ready panels cut to exact dimensions for scaffolding or flooring systems.

5. Does it meet international safety standards?

Yes, products are tested to EN 314-2 Class 3 and BS 1088, ensuring performance under wet conditions.

Conclusion

Anti-slip film faced plywood represents a perfect combination of safety, strength, and sustainability. For scaffolding and flooring, it offers secure footing, water resistance, and long-term value unmatched by conventional wood panels. Contractors and importers looking to enhance site safety while maintaining cost efficiency can rely on Vietnam-made anti-slip plywood as a trusted choice.

At TT Plywood, we manufacture and export premium film faced plywood, anti-slip panels, and birch plywood to global markets. Our products are FSC-certified, EN 314-2 tested, and engineered for durability in demanding applications.

📩 Contact us today to request a quote or technical datasheet for your next project.

Tags :

anti-slip Film Faced Plywood

Film Faced Plywood Vietnam

plywood

TT PLYWOOD

Vietnamese plywood