-

-

-

Total payment:

-

FSC Certified Film Faced Plywood: Eco-Friendly Choices for Sustainable Construction

Posted by Thanh Uyên at 20/11/2025

Across Europe and the United States, the construction sector is undergoing one of its most significant shifts in decades. Environmental policies, due-diligence requirements and sustainability reporting are no longer optional frameworks but binding obligations that shape procurement decisions. As a result, demand has increased sharply for materials that are not only durable, cost-efficient and high performing, but also ethically sourced and fully traceable. FSC Certified Film Faced Plywood has emerged as a standout material within this transition.

Companies today face rising expectations from regulators, investors and clients regarding ESG performance and supply-chain transparency. Traditional plywood without documented origins is increasingly viewed as a compliance risk. In contrast, FSC-certified products offer a verifiable path to sustainability while maintaining the technical reliability that large construction projects depend on. The following analysis explores why this material is gaining prominence in both markets and how it aligns with the direction of international construction standards.

Understanding FSC-Certified Film Faced Plywood

Film Faced Plywood is an engineered panel designed for high-performance environments such as concrete formwork, industrial moulding and structural systems requiring repeated reuse. The panel is constructed from multiple layers of hardwood or mixed hardwood veneers, bonded with waterproof adhesive and finished with a phenolic surface film. This film enhances moisture resistance, provides a smooth finish and protects the core from mechanical stress.

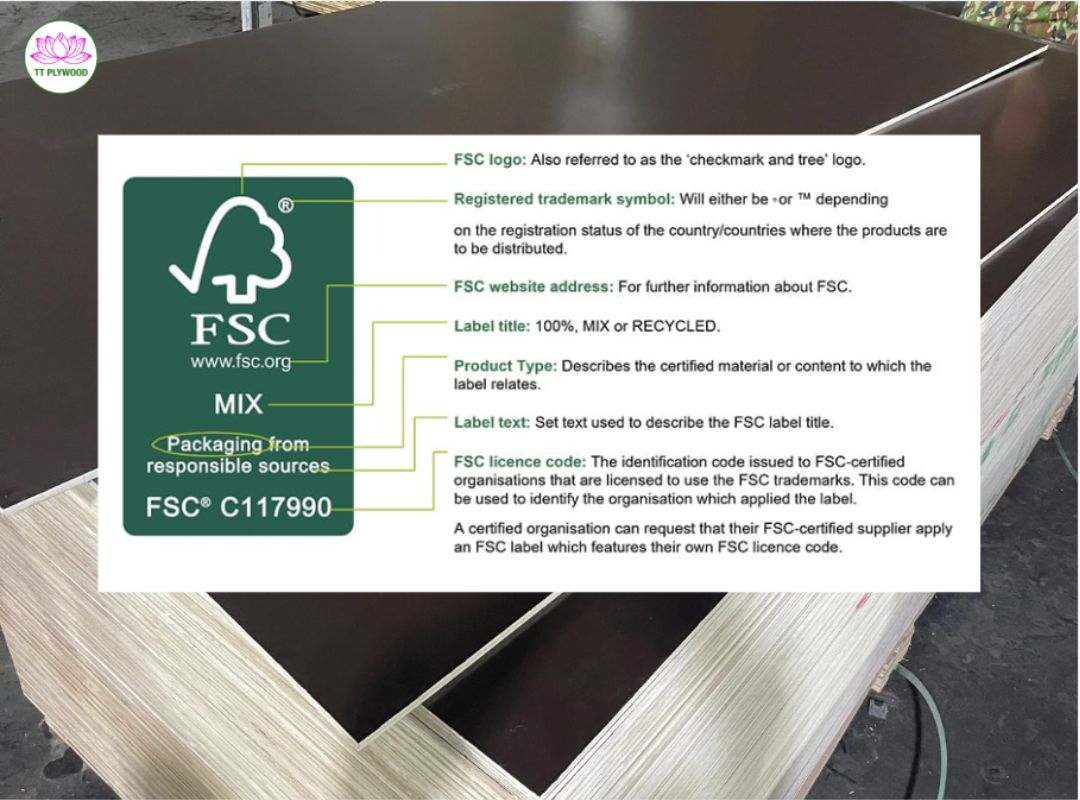

When the plywood is FSC-certified, it meets the strict criteria of the Forest Stewardship Council. The certification ensures the wood comes from responsibly managed forests that support biodiversity, protect workers’ rights and uphold community welfare. In addition, FSC Chain of Custody certification requires complete traceability at each stage of processing and distribution, allowing importers in the EU and US to access documentation that supports regulatory compliance.

This combination of environmental accountability and technical dependability is exactly what many modern construction companies seek, especially those working in markets where sustainability is embedded into building codes, public procurement standards and investment requirements.

Why FSC Film Faced Plywood Appeals to the EU and US Markets

Both European and American industries are navigating an evolving regulatory landscape. In Europe, the EU Deforestation Regulation introduces strict obligations to verify that imported timber products do not contribute to deforestation or come from high-risk regions. In the United States, CARB and EPA TSCA Title VI continue to shape standards for composite wood, emissions and safety.

In this context, companies importing or using uncertified plywood face unnecessary risk. FSC-certified materials, on the other hand, offer documentation that aligns with due diligence frameworks and supports sustainability audits. Beyond compliance, many architects, engineers and investors now require certified timber as part of project specifications, especially for public infrastructure, commercial developments and green building initiatives.

Market trends also indicate that customers prefer working with suppliers capable of providing consistent quality, clear traceability and lower environmental impact. FSC Film Faced Plywood effectively addresses these expectations while maintaining the functional performance required for large-scale construction.

Sustainability as a Commercial Advantage

Sustainability has evolved into a measurable business asset. Construction companies in the EU and US must often demonstrate environmental performance in order to qualify for competitive tenders or meet the reporting expectations of investors and regulators. FSC-certified plywood contributes directly to this process.

It supports green building certifications such as LEED, BREEAM and DGNB, all of which evaluate the environmental responsibility of materials used in a project. It also enhances ESG reporting by providing independently verified evidence of responsible sourcing. This documentation becomes particularly valuable in the context of supply-chain audits, environmental impact assessments and corporate sustainability reporting.

From an environmental standpoint, FSC-certified plywood contributes to lower carbon emissions across the product lifecycle, encourages responsible forest management and reduces construction waste due to its improved durability and reuse potential. These advantages directly influence how companies position themselves in competitive markets, especially when sustainability and compliance are central to project evaluation.

Applications of FSC Film Faced Plywood in Modern Construction

Film Faced Plywood is a core material in concrete formwork for slabs, beams and columns. Its smooth surface allows concrete to cure evenly, reducing the need for post-finishing. Because it resists water and mechanical pressure, it remains stable after repeated cycles of installation and removal, making it ideal for both civil engineering projects and industrial construction.

In addition to traditional applications, the material is widely used in modular and prefabricated construction systems. These rapidly expanding sectors require materials capable of performing under repeated assembly and transportation. The reliability, lifespan and traceability offered by FSC-certified plywood align perfectly with these requirements. As both markets place increasing value on sustainability and efficiency, FSC Film Faced Plywood continues to gain relevance as a versatile, future-ready solution.

Quality Standards and Performance Considerations

To meet the expectations of EU and US markets, Film Faced Plywood must achieve high standards not only in sourcing but also in technical performance. The construction of the core is a key factor. Dense hardwood species such as eucalyptus or acacia provide greater structural stability, reduced deformation and improved load-bearing capacity. These properties are essential for formwork that must withstand pressure and maintain shape across multiple use cycles.

Adhesive quality also plays a major role. Panels designed for demanding markets typically use strong waterproof bonding systems and must comply with CARB P2 and EPA TSCA Title VI emission standards. Surface film weight and quality determine resistance to abrasion, water ingress and blistering. All these factors work together to define the durability and consistency expected by construction professionals.

To explore more about plywood options and compliance solutions from Vietnam, TT Plywood provides additional insights in its article Birch Plywood in Vietnam at https://ttplywood.com/birch-plywood-in-vietnam and related updates in the company’s news section at https://ttplywood.com/news.

Advantages of FSC Film Faced Plywood

• Certified sustainable sourcing with full traceability that meets strict compliance expectations in Europe and the United States.

• High durability that allows panels to be reused many cycles, supporting cost efficiency and reducing environmental waste.

Benefits for Importers and Construction Companies

• Strong support for ESG objectives and ease of alignment with major green building frameworks.

• Reduced regulatory exposure by ensuring compatibility with EUDR, CARB and other due-diligence and documentation demands.

Companies seeking to strengthen their sustainability commitments, improve project reliability and meet international compliance requirements will find FSC-certified Film Faced Plywood to be one of the most forward-looking material choices available. TT Plywood supports importers, contractors and distributors across Europe and the United States with complete FSC certification, EUDR-ready supply-chain documentation, CARB/EPA-compliant products and consistent manufacturing standards.

We welcome organisations looking for dependable sourcing, sample evaluation or detailed technical consultation. Our team is ready to assist with quotations, logistics solutions and compliance documentation tailored to your market.

📞Hotline/WhatsApp/Line/Kakao: +84 32 694 2288

📧Email: info@ttplywood.com

🌐Website: https://ttplywood.com/

FAQ

Why is FSC certification important for Film Faced Plywood?

It verifies that the wood was sourced responsibly, supports forest conservation and meets documentation requirements essential for EU and US importers, reducing compliance risks.

How many reuse cycles can FSC Film Faced Plywood typically achieve?

Panels generally achieve eight to twenty cycles depending on use conditions, maintenance practices and the quality of the core and film, resulting in improved cost performance.

Is FSC-certified plywood suitable for demanding construction environments?

Yes. Its durability, density and waterproof bonding systems make it appropriate for large infrastructure projects, industrial construction and modern formwork systems.

References (Harvard Style)

Forest Stewardship Council (FSC). 2023. Principles and Criteria for Forest Stewardship. Bonn: FSC International.

European Commission. 2024. EU Deforestation Regulation: Compliance Guidance for Timber Products. Brussels: Publications Office of the European Union.

U.S. Environmental Protection Agency (EPA). 2022. TSCA Title VI Formaldehyde Standards for Composite Wood Products. Washington, D.C.