-

-

-

Total payment:

-

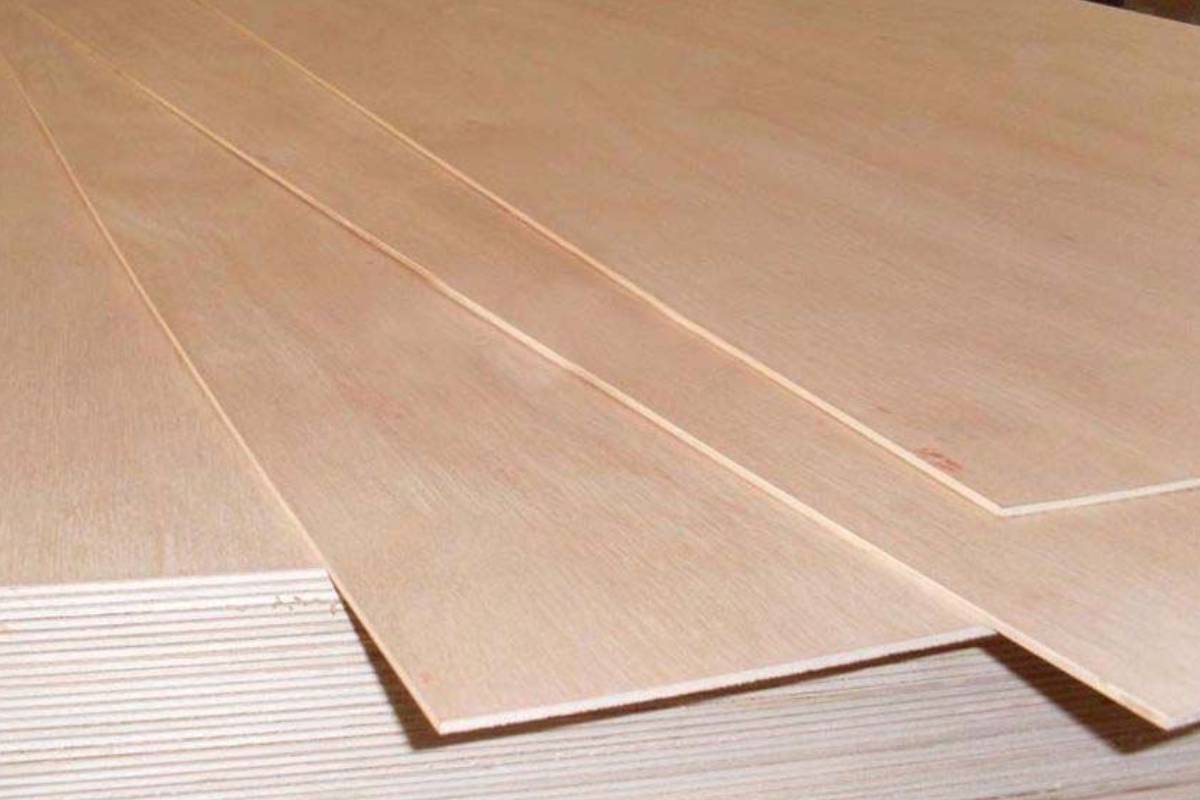

How to Choose the Right Packaging Plywood Thickness

Posted by Kiều Trang at 17/10/2024

Choosing the right thickness of plywood for packaging is an important decision in the packaging and transportation of goods. Thickness not only affects product protection but also determines costs and usage efficiency. Here’s a detailed guide on how to select the appropriate thickness of plywood packaging for your needs.

1. Determine the Purpose of Use

- Lightweight Goods: For lightweight products such as small electronics, clothing, or light furniture, you can opt for plywood with a thickness of 3mm to 5mm. These products typically do not require high durability, and thinner plywood can help reduce costs.

- Heavy Goods: For heavier items such as machinery, large electronic devices, or heavy furniture, a thickness of 9mm to 12mm or even more is advisable. Greater thickness enhances load-bearing capacity and reduces the risk of damage from impacts during transit.

2. Consider the Transportation Environment

- Dry Transport: If goods will be transported in dry conditions, you may choose a thinner thickness while still ensuring quality. However, it's important to select plywood with good impact resistance to protect the items.

- Wet Transport: In cases where goods will be exposed to humidity or wet environments, thicker plywood is recommended. Plywood with moisture-resistant coatings will be an optimal choice, helping to protect products from mold and damage.

3. Check Load-Bearing Properties

- The thickness of plywood directly affects its load-bearing capacity, durability, and stiffness. You should refer to standards such as ASTM or EN for compression and bending strength to ensure that the product meets your requirements. Testing the plywood under real conditions can also help you accurately assess its protective capabilities.

4. Costs and Budget

- Thicker plywood typically comes with higher costs. You need to consider your budget to choose a suitable thickness that still ensures quality. If your budget is limited, consider using medium-thickness plywood that meets essential protective criteria for your goods.

5. Characteristics of the Inner Product

- If the product inside has a special shape, is fragile, or needs additional protection, you should choose thicker plywood to ensure safety. For example, packaging glassware, electronic devices, or fragile items requires greater thickness to minimize the risk of damage during transport.

6. Consult with Suppliers

- Always consult with your plywood supplier for specific advice on the appropriate thickness for your products. Suppliers typically have experience and can provide detailed information about each type of plywood, helping you make a more informed decision.

7. Testing and Evaluation

- If possible, experiment with different thicknesses of plywood to evaluate their protective capabilities and suitability for your products. Practical testing can help you identify the strengths and weaknesses of each plywood type, allowing you to make the best choice.

8. Analyze Specific Situations

- Consider the specific situations that your goods will face. If you frequently transport items through challenging terrains, opting for thicker plywood can ensure better safety. Additionally, consider the transportation time, as items transported for longer durations may require greater thickness for effective protection.

9. Aesthetic and Branding Considerations

- Besides protective capabilities, the aesthetics of the plywood should also be considered. Attractive and professional packaging not only protects goods but also enhances your brand value. If necessary, consider using plywood that is suitable for printing to create an appealing design for your product packaging.

10. Market Trends and Customer Requirements

- Monitoring market trends and customer demands is also crucial. If your customers request specific packaging standards, make sure you meet those requirements by choosing the right thickness. Customer satisfaction plays an important role in retaining and attracting new clients.

Choosing the right thickness of plywood for packaging not only affects the quality of product protection but also influences costs and production efficiency. Carefully consider factors such as the purpose of use, transportation environment, product characteristics, and budget to make an informed decision. A correct choice will help you better protect your goods, minimize losses during transport, and enhance customer satisfaction.