-

-

-

Total payment:

-

EN vs HPVA: The Birch Plywood Grading Guide

Posted by Thanh Uyên at 23/10/2025

1. Why Birch Plywood Grading Matters

For European and North American importers, Birch Plywood has long been a benchmark of stability, strength, and aesthetics. But one panel can look and perform very differently from another and much of that difference comes down to grading.

The European grading system (EN 635-2 and EN 635-3) establishes a standardized way to evaluate surface quality, knot repair, and veneer uniformity. This helps importers, furniture makers, and contractors choose the right plywood for their projects and pricing tiers.

As sanctions and supply shifts have reshaped the market, Vietnam plywood manufacturers like TT Plywood have become reliable partners producing Birch panels that fully comply with EN classifications and FSC standards, providing a competitive, sustainable alternative to Baltic Birch.

2. The European Grading System Explained

Under EN 635-2, veneer surfaces are graded based on visual appearance from A (highest) to C (lowest) with a second grade for the back side.

A panel marked B/BB, for example, has a higher-quality front and a standard-quality back.

European Birch Plywood Grades (EN 635-2):

- Grade A: Perfectly smooth, even color, no knots or patches. Ideal for decorative furniture, interior panels, and visible architectural surfaces.

- Grade B: Allows a few small, sound knots and minimal color variation. Natural-looking surface used in furniture and cabinetry.

- Grade BB: Permits repaired knots and plugs. Strong, practical, and economical for backs, interiors, and veneered surfaces.

- Grade CP (Construction Panel): Repaired and sanded with visible imperfections, suitable for flooring, crates, or industrial use.

- Grade C: Rougher, un-repaired face, may include splits or open knots. Used in packaging, formwork, or concealed construction.

Each sheet is labeled with its face and back grade, giving buyers full transparency on visual quality and expected cost.

3. How the Grades Differ Visually

Even though all Birch Plywood is strong and dimensionally stable, appearance is what sets the grades apart. For industries where design and visibility matter such as furniture or retail interiors these distinctions are crucial.

Typical face/back combinations:

- A/B: For luxury furniture and visible architectural joinery.

- B/BB: Most common balance between quality and price.

- BB/CP: For durable but hidden uses like floors or crate panels.

- CP/C: For industrial packaging and temporary formwork.

(Birch Plywood Grade BB-TT Plywood)

4. Technical Properties Behind the Grades

Grading isn’t only about looks. Each quality level corresponds to performance standards defined by EN 314-2 (bonding) and EN 717-1 (emission). Birch Plywood is prized for its dense, fine-grain veneers and consistent structure qualities that make it superior to poplar or tropical plywoods.

Technical factors that determine quality:

- Bonding class: Class 1 for dry interiors; Class 2 for humid conditions; Class 3 for exterior formwork.

- Formaldehyde emission: E0 (≤0.05 mg/m³) or E1 (≤0.124 mg/m³), safe for indoor environments and compliant with CARB P2.

- Density: 650–700 kg/m³, ensuring excellent screw-holding capacity and rigidity.

- Thickness tolerance: ±0.2 mm for precision in CNC machining and cabinetry.

- Surface preparation: Sanded on both sides for consistent veneer finishing and adhesive bonding.

These parameters guarantee that even lower-grade panels from certified manufacturers maintain high mechanical integrity an important assurance for European importers.

5. Matching Grades to Applications

Selecting the correct grade is not only a matter of aesthetics but also practicality and cost-efficiency. Importers and manufacturers often combine multiple grades across one production line using premium veneers for visible areas and standard ones for internal components.

Grade Application Guide:

- A/B: Furniture fronts, decorative walls, acoustic panels, yacht interiors.

- B/BB: Cabinet bodies, shopfitting, veneered furniture bases.

- BB/CP: Flooring substrates, shelves, industrial partitions.

- CP/C: Pallets, crates, temporary flooring, or reusable formwork.

By optimizing grades this way, businesses can reduce material costs by up to 30% without compromising structural performance or brand quality.

(Birch Plywood Grade B-TT Plywood)

6. Birch Plywood Quality from Vietnam

In the past, most Birch Plywood came from Northern Europe. But after trade restrictions and raw material shortages, Vietnam has become a trusted production center for plywood export to the EU and US.

Vietnamese factories source imported Birch veneers often from Europe or China and combine them with plantation-grown Eucalyptus or Rubberwood cores. This hybrid structure maintains Birch’s visual appeal while enhancing sustainability and reducing costs.

👉 Related reading: Vietnam’s FSC Plywood: The New Alternative to Costly Chinese Imports

Each sheet undergoes grading under EN 635-2, bonding tests per EN 314-2, and emission checks for E0/E1 compliance. With traceable FSC documentation, Vietnam plywood manufacturers like TT Plywood ensure every batch meets EU Timber Regulation (EUTR) and U.S. Lacey Act requirements.

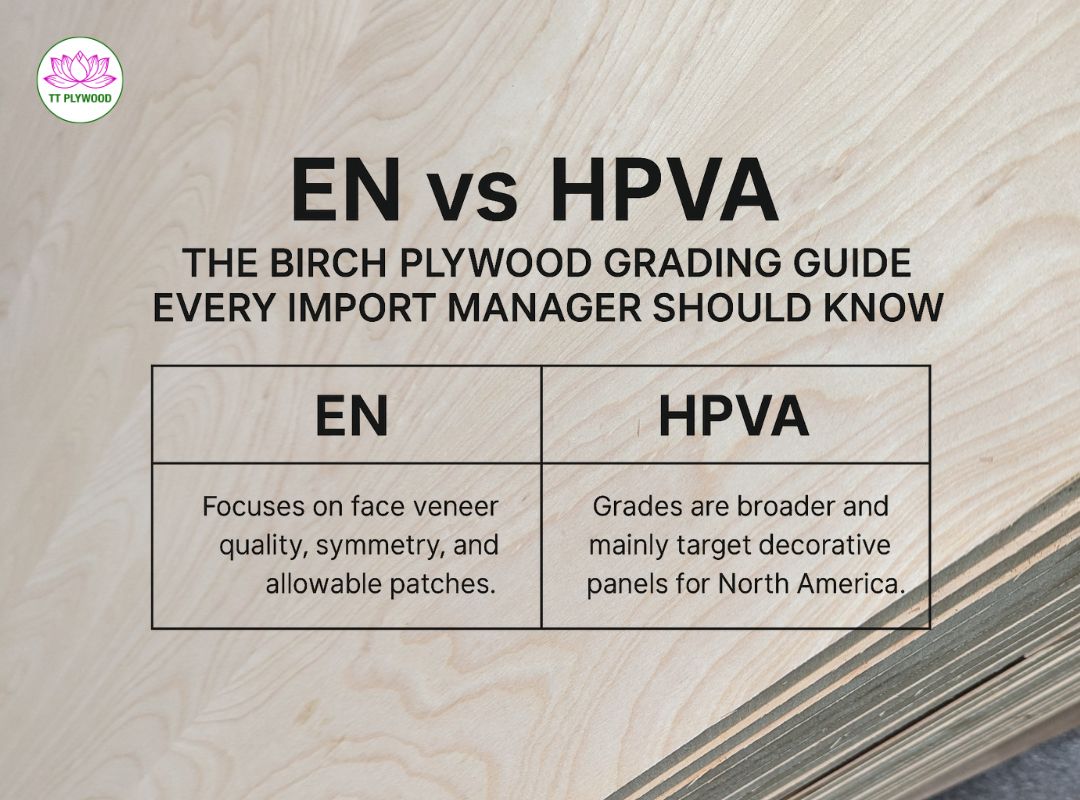

7. Key Differences from Other Grading Systems

Unlike the U.S. HPVA standard (which uses AA, A, B, C, D), the European EN 635-2 system is more detailed about visual defects and repairs.

- EN grades focus on face veneer quality, symmetry, and allowable patches.

- HPVA grades are broader and mainly target decorative panels for North America.

For importers operating in EU markets, EN-graded Birch Plywood provides more predictable visual outcomes and aligns with CE-marking requirements a crucial factor for interior designers and construction contractors.

8. Cost and Value Considerations

The price gap between grades can be substantial: A/B Birch Plywood may cost up to 40% more than BB/CP. However, the performance remains similar; the difference lies primarily in surface appearance.

Many European importers adopt a mixed-grade strategy pairing high-grade fronts with economical backs. This combination maximizes efficiency and reduces waste.

Additionally, sourcing from Vietnam plywood manufacturers offers consistent supply, competitive pricing, and flexible order volumes compared with Baltic producers. With container-ready stock, companies like plywood export TTP (TT Plywood) can meet both small-batch and high-volume demand.

9. Sustainability and Certification

Sustainability now defines purchasing decisions across Europe and North America. Birch Plywood from Vietnam aligns perfectly with these expectations:

- FSC-certified veneer sourcing from responsibly managed forests.

- Low-emission adhesives (E0/E1, CARB P2) to ensure indoor air safety.

- Efficient core utilization using plantation-grown Eucalyptus and Rubberwood.

- Traceable supply chain for EUDR and Lacey Act compliance.

This eco-conscious production model has made Vietnam one of the most reliable exporters of certified Birch Plywood globally.

(Birch Plywood Grade CP-TT Plywood)

10. Why Choose TT Plywood

TT Plywood represents the new generation of Vietnam plywood manufacturers who merge European technical standards with Southeast Asian efficiency. Each panel is inspected by trained quality teams and labeled by grade for full transparency.

Why global buyers trust TTP:

- European EN grading compliance for face/back labeling.

- FSC, CE, and CARB certifications.

- Consistent thickness control and superior bonding strength.

- Competitive lead times with ready-to-ship inventory.

TTP’s clients in Germany, France, and the Netherlands frequently note that its Birch panels rival Baltic equivalents in performance, while offering shorter production cycles and more flexible customization.

Choosing the right Birch Plywood grade can make or break a project’s visual impact and cost efficiency. Whether you need flawless A/B panels for luxury interiors or durable BB/CP sheets for furniture production, plywood export TTP (TT Plywood) guarantees precision, certification, and sustainability.

👉 Contact TT Plywood today to discuss your project needs, or explore our related guide: Vietnamese Birch Plywood: The Smart Alternative to Baltic Birch.

FAQs About European Birch Plywood Grades

Q1: What is the difference between EN and US grading?

EN 635-2 uses A/B/BB/CP/C, focusing on veneer defects and repairs. HPVA uses AA/A/B/C/D, based on decorative quality.

Q2: Are lower grades like BB/CP still strong?

Yes. Structural strength depends on bonding and core quality, not just face veneer. Even BB/CP panels meet Class 2 or 3 bonding under EN 314-2.

Q3: Can Vietnamese Birch Plywood replace Baltic Birch?

For 90% of furniture and construction applications — absolutely. It offers similar density and mechanical performance with better supply stability.

Q4: What certificates should importers request?

FSC, CE, and CARB P2 for emissions, plus EN 314-2 bonding test reports.

Conclusion

Birch Plywood graded under the European EN 635-2 system offers clarity, reliability, and transparency. Understanding how A, B, BB, CP, and C differ helps buyers source the right material for every purpose from premium interiors to industrial packaging.

Vietnam’s TT Plywood stands out for aligning with these standards while providing the efficiency, sustainability, and flexibility global markets demand. Whether you are a distributor in the EU or a contractor in the U.S., TT Plywood ensures every panel meets European-grade performance sheet after sheet.

References

BS EN 635-2:2017. Plywood – Classification by surface appearance. London: British Standards Institution.

BS EN 314-2:1993. Plywood – Bonding quality requirements. Brussels: CEN European Committee for Standardization.

BS EN 717-1:2004. Wood-based panels – Formaldehyde release. Brussels: CEN.

TT Plywood (2025). Vietnamese Birch Plywood: The Smart Alternative to Baltic Birch. Available at: https://ttplywood.com/vietnamese-birch-plywood-the-smart-alternative-to-baltic-birch (Accessed: 23 October 2025).