-

-

-

Total payment:

-

Birch Plywood for Logistics: Pallets and Crates Built to Last

Posted by Thanh Uyên at 21/10/2025

1. The Backbone of Modern Logistics

In the global logistics chain, materials define performance. Every pallet, crate, and container must endure heavy loads, long-distance transport, and unpredictable weather. While traditional softwoods and plastic alternatives dominate some markets, Birch Plywood has quietly become the preferred material for companies prioritizing durability, efficiency, and sustainability.

As global trade expands, EU and US importers are rethinking how they package and transport goods. Many are turning toward Vietnam plywood manufacturers such as TT Plywood, who deliver high-grade, certified Birch Plywood engineered for export packaging.

2. Why Birch Plywood Outperforms Solid Wood

Unlike solid timber, Birch Plywood is composed of multiple thin veneer layers, cross-bonded with strong adhesives to resist bending, cracking, and moisture. Each layer is rotated 90 degrees to the one below, creating unmatched dimensional stability and strength-to-weight performance.

For logistics operations, this translates into pallets and crates that remain sturdy after multiple shipping cycles reducing waste and replacement costs.

Key advantages include:

- High load capacity: Handles heavy products such as machinery, electronics, and industrial components.

- Lightweight construction: Reduces shipping weight compared to solid hardwood.

- Moisture resistance: Prevents warping during overseas transport.

- Sustainability: Sourced from FSC-certified plantations, minimizing deforestation risk.

In an age of carbon accountability, Birch Plywood offers companies an eco-friendly material that performs under pressure.

3. How Birch Plywood Pallets and Crates Are Made

Modern plywood-based logistics packaging is engineered with precision. Vietnamese manufacturers such as TTPlywood use a combination of imported Birch veneers and plantation-grown cores (Eucalyptus, Rubberwood) for balanced strength and affordability.

Production involves:

- Hot pressing: Multiple veneer layers bonded under high temperature and pressure.

- Edge sealing: Protects against moisture penetration during storage and transit.

- Sanding & finishing: Smooth surfaces suitable for printing, branding, and export marking.

Each panel is tested for bending strength, bonding quality (EN 314-2 Class 3), and moisture resistance to ensure compliance with EU and US standards.

4. Birch Plywood vs. Other Packaging Materials

Companies evaluating materials for logistics often compare Birch Plywood to pine, plastic, or MDF. The differences are striking.

Comparison Snapshot:

- Birch Plywood: High density (~650 kg/m³), multi-layer strength, reusable up to 10–20 cycles.

- Solid Wood: Inconsistent grain structure, vulnerable to cracking.

- Plastic Pallets: Durable but expensive, non-biodegradable.

- MDF/Particle Board: Cheap but weak against humidity or load pressure.

For export logistics where weight, hygiene, and durability matter, Birch Plywood delivers the best balance between cost and performance.

5. Benefits for Exporters and Manufacturers

The logistics industry operates on efficiency. Each kilogram saved or each reuse achieved directly impacts profit margins. Birch Plywood packaging supports these priorities through measurable advantages:

For Exporters:

- Reduced freight costs thanks to lighter pallet weight.

- Fewer breakages and rejected shipments.

- Compliance with ISPM-15 (no fumigation required).

For Manufacturers:

- Faster assembly with precision-cut panels.

- Consistent quality for automated handling systems.

- Lower lifetime cost due to reusability.

6. The Rise of Vietnamese Birch Plywood

Since sanctions on Russian and Belarusian wood, global buyers have looked to Vietnam for reliable Birch alternatives. The country has become a hub for plywood export, combining sustainable sourcing, competitive pricing, and international certification.

Vietnamese Birch Plywood produced with 100% plantation cores and imported Birch veneers offers consistent thickness, high bonding strength, and strict formaldehyde limits (E0/E1, CARB P2).

Suppliers like plywood export TTP (TT Plywood) provide complete traceability and quality documentation, helping EU and US buyers meet due diligence requirements.

👉 Explore related insights: Vietnam’s FSC Plywood: The New Alternative to Costly Chinese Imports

7. Sustainability and Compliance

In Europe and North America, regulations such as EUDR (EU Deforestation Regulation) and the US Lacey Act are shaping sourcing strategies. Birch Plywood from Vietnam aligns perfectly with these standards:

- FSC-certified raw materials ensure sustainable forestry.

- CARB P2 and E0/E1 adhesives guarantee low emissions for safer workplaces.

- Controlled supply chains enable traceability from forest to shipment.

By partnering with certified Vietnam plywood manufacturers, importers can market their packaging as both high-performance and environmentally responsible.

8. Real-World Applications

From electronics exporters in Germany to furniture suppliers in California, Birch Plywood pallets and crates are becoming industry staples. Their consistent density and smooth finish support laser marking, branding, and custom designs. The ability to stack, reuse, and ship across climates—from humid ports in Asia to freezing warehouses in Europe makes them indispensable for modern logistics.

Two common applications include:

- Heavy machinery packaging: Birch’s strength supports engines, tools, and parts over long transport routes.

- Consumer goods exports: Lightweight yet durable crates reduce total shipment costs.

9. Why Choose TT Plywood

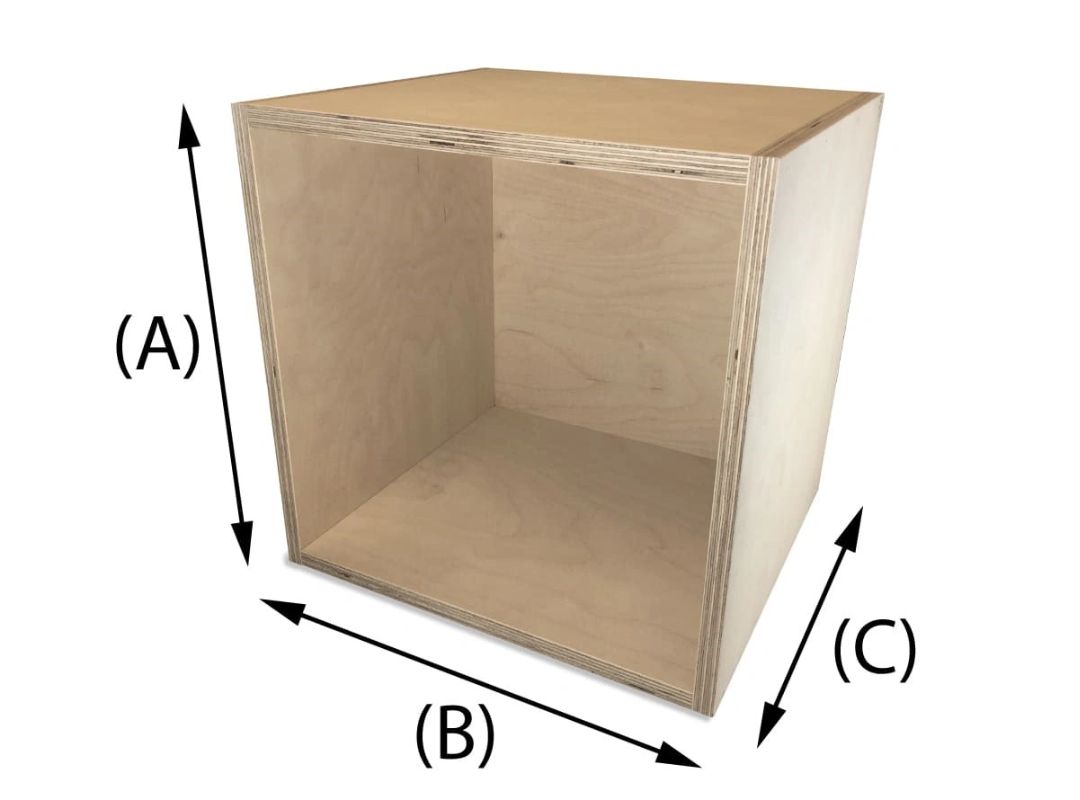

TT Plywood combines technical expertise with export reliability. Every panel undergoes strict quality control moisture, glue bond, and thickness tolerance are checked on every batch. Products are compliant with FSC, EUTR, CE and CARP P2 standards, while custom pallet and crate panels can be ordered to fit specific dimensions.

The company’s export network spans over 30 countries, including the EU, US, Australia, and Japan. Ready-to-ship stock and responsive logistics make TTPlywood a preferred partner for buyers seeking dependable plywood export from Vietnam.

10. FAQs About Birch Plywood for Logistics

Q1: How many times can a Birch Plywood pallet be reused?

Depending on handling and environment, up to 15–25 times—significantly more than traditional wood.

Q2: Does it meet EU and US import regulations?

Yes. TT Plywood’s Birch panels meet FSC, CARB P2, and CE standards, complying with EU Timber Regulation (EUTR) and the U.S. Lacey Act.

Q3: Can it replace solid wood for heavy goods?

Absolutely. Its layered structure provides comparable strength while being lighter and easier to handle.

Q4: Is it environmentally friendly?

Yes. It’s made from renewable plantation wood and low-emission adhesives, reducing carbon footprint compared to conventional timber.

11. Conclusion – Building a Stronger Supply Chain

In an era of rising shipping costs and stricter environmental standards, Birch Plywood stands as the smarter, more sustainable alternative for global logistics. Its strength, stability, and reusability make it indispensable for pallets and crates that truly last.

By partnering with plywood export TTP (TT Plywood), importers and manufacturers gain access to certified quality, dependable supply chains, and eco-compliant materials—backed by the craftsmanship of Vietnam’s most trusted plywood producer.

👉 Contact TT Plywood today to discuss your plywood needs and discover how Birch Plywood can strengthen your logistics from the inside out.

References

FAO (2024) Global Forest Products Facts and Figures 2023. Food and Agriculture Organization of the United Nations.

European Commission (2024) EU Deforestation Regulation (EUDR): Implementation Guide. Brussels: European Union Publications Office.

TT Plywood (2025) Vietnam’s FSC Plywood: The New Alternative to Costly Chinese Imports. Available at: https://ttplywood.com/vietnam-s-fsc-plywood-the-new-alternative-to-costly-chinese-imports (Accessed: 21 October 2025).