-

-

-

Total payment:

-

Hardwood Plywood Grades: AA, A, B, C Explained | Buyer’s Quick Guide

Posted by Thanh Uyên at 17/10/2025

Hardwood plywood is prized for its strength, clean finish, and machining reliability in cabinetry, furniture, wall panels, and architectural millwork. Yet buyers often get tripped up by the letter codes on product sheets: AA, A, B, C. These face/back veneer grades are not just cosmetic—they directly affect price, yield, and the amount of finishing work required on site. This guide demystifies grading so importers, contractors, and fabricators can spec the right panel the first time and avoid costly rework.

Note: “grade” refers to surface veneer quality. It sits alongside other crucial specs core type, thickness tolerance (calibrated vs standard), bonding class, and emissions. For a fuller primer on plywood types and cores, see What Is Plywood? Everything You Need to Know.

How Grading Works (Face/Back Logic)

A hardwood plywood label typically lists two letters (e.g., A/B or B/C). The first is the face; the second is the back. A higher letter means a cleaner, more uniform surface with fewer patches and repairs. Grades are assigned at the veneer level and verified after pressing and sanding. Because grade drives yield (how much of the sheet can be shown in view), it’s also the biggest lever on price.

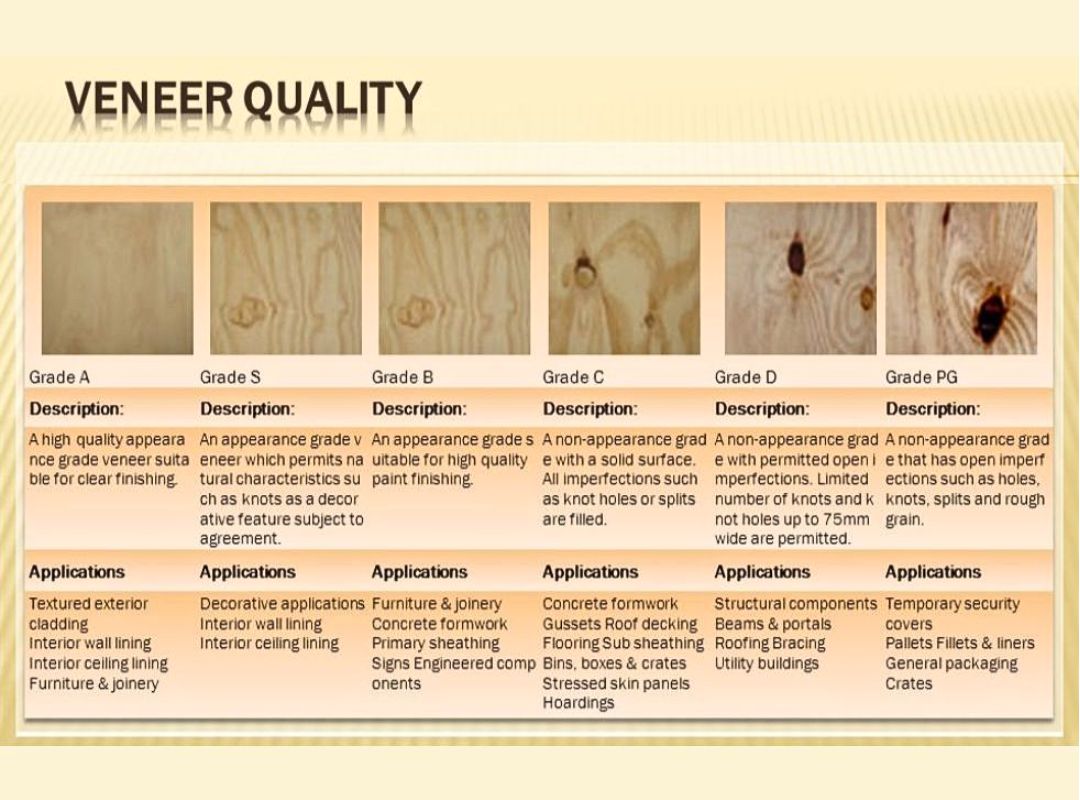

What Each Grade Means (AA, A, B, C)

Use this quick reference to align expectations with real-world surfaces.

Veneer grade definitions at a glance:

- AA (Premium architectural face) – Nearly flawless, uniform color and grain, minimal or no patches. Chosen for high-end panels that will be finished clear or stained and seen up close (reception desks, store fixtures, premium doors).

- A (Cabinet face) – Smooth and clean with small, well-executed repairs allowed; sands to a paint- or stain-ready surface. Ideal for built-ins, casework, and furniture faces.

- B (Utility/show face) – Sound veneer with color variation, knots/repairs within limits. Good for semi-visible areas, end panels, and paint-grade millwork.

- C (Back/structural face) – Visible defects and patches allowed; best behind the scenes. Often specified as the back of A/C or B/C panels to control cost.

When appearance matters retail fronts, living-area millwork, premium kitchens—AA or A faces save finishing hours. For utility cabinets or painted shop fixtures, B/C often delivers the best value.

Grades vs. Cores, Bonding, and Emissions

Grade isn’t everything. A perfect face on the wrong core can still cause callbacks. Match the surface to the inside:

- Core options. For ultra-flat cabinetry and clean edges, many buyers choose birch-faced panels with plantation hardwood cores (eucalyptus/acacia) for strength and cost control. Curious about birch options? Read Differences Between Baltic Birch and Standard Birch Plywood.

- Bonding class. Interior work typically uses MR/Interior glue; humid zones benefit from exterior/WBP. For wet job sites or mixed exposure, consider film-faced plywood or exterior bonding see.

- Emissions. EU/US markets increasingly demand low-formaldehyde (E0/E1) / CARB/EPA compliance. Documentation and lot traceability are critical; see Plywood Certifications Explained.

Typical Use Cases by Grade

AA faces dominate premium interiors, A faces lead in cabinet doors and fronts, B faces suit paint-grade or semi-visible panels, and C faces are chosen as backs/liners to optimize budgets. Remember: the back still matters for panel balance and screw-holding; a sound C back can save money without sacrificing performance.

Tolerances and “Calibrated” Panels

For CNC machining and high-speed production lines, calibrated plywood sanded to tight thickness tolerance reduces setup time and edge tear-out. If you’re cutting dadoes or pocketing hundreds of parts, consistent thickness often saves more money than dropping a face grade.

Quick Selection Guide (Save Time on Specs)

Use this buyer-friendly matrix to pair the right face/back with your application.

Choose like a pro:

- High-end architectural panels (clear/stain): AA/A with balanced core; calibrated thickness.

- Kitchen cabinets & built-ins (paint or stain): A/A or A/B faces; low-emission glue line; calibrated for CNC.

- Retail fixtures & end panels (paint-grade): B/B or B/C on stable core; exterior bond if transport moisture is a risk.

- Utility liners, backs, substrates: C/C or B/C; prioritize flatness and screw-holding over face perfection.

- Humid sites or repeated handling: Exterior/WBP bond; consider film-faced options for durability.

Cost, Yield, and Waste (The Value Equation)

Upgrading from B to A (or A to AA) raises sheet price, but can reduce finishing hours, filler use, and rejects especially on visible faces. Conversely, dropping the back from B to C often cuts cost without risk if the backside is hidden. Many EU/US fabricators standardize on A/C calibrated for kitchen boxes: beautiful outside surfaces, economical backs, and predictable machining.

Common Buyer Pitfalls (and How to Avoid Them)

The most frequent issues aren’t about grade at all they’re about mismatched expectations. Buyers may order A/C but expect AA uniformity, or they specify AA/A and still want exterior bonding with E0 emissions at commodity pricing. Align the triangle: face grade, core/bond, and documentation. Request recent test reports and photos from production lots before shipment.

Frequently Asked Questions (FAQ)

1) Is AA always worth it for cabinets?

For premium, stain-grade fronts yes. For painted kitchens, an A face usually delivers the same finished look with less cost.

2) Can I mix grades in one job?

Absolutely. Many contractors combine A/A for doors and A/C for carcasses to balance aesthetics and budget while keeping color/texture consistent.

3) Does a C back risk warping?

Not if the panel is well-balanced. Warping is more about core construction and moisture than the letter on the back. Ask for calibrated panels on stable plantation cores.

4) What if I need both beauty and moisture resistance?

Specify A/A (or A/B) with exterior/WBP glue. For harsh handling or wet pours, step up to film-faced plywood where the surface carries a phenolic film.

5) How do I verify low-formaldehyde claims?

Request current CARB/EPA reports and factory declarations matched to batch/lot numbers. In the EU, keep documents for due diligence and audits.

Conclusion

Understanding AA, A, B, C grades lets you set precise expectations and pay only for the face quality you truly need. Combine the right face/back with a stable core, proper bonding class, and low-emission documentation, and you’ll get panels that machine cleanly, finish beautifully, and pass compliance checks without friction. At TT Plywood, we manufacture export-grade hardwood plywood tailored to EU and U.S. specifications calibrated thickness, FSC-verified sources, CARB/EPA emissions, and EN bonding classes. Whether you need AA architectural faces or cost-optimized A/C for production cabinetry, we can match grade to application and budget.

Contact TT Plywood to request grade-matched samples, current test reports, and a landed-cost quotation for your route.

📞Hotline/WhatsApp/Line/Kakao: +84 32 694 2288

📧Email: info@ttplywood.com

🌐Website: https://ttplywood.com/