-

-

-

Total payment:

-

Reusable Film Faced Plywood: Maximize Your Investment with These Pro Tips

Posted by Thanh Uyên at 10/10/2025

Why reusability is the real profit lever

Every pour leaves marks on the structure and on your panels. If the formwork face survives, you reuse it; if it chips, swells, or delaminates, you pay again. That’s why reusability is the true lever behind cost-per-pour. Film faced plywood earns its keep when you combine three things: correct specification, disciplined handling, and consistent maintenance. Do that well and you stretch your panels through many cycles, keep schedules tight, and deliver better architectural finishes.

What makes a sheet reusable (or not)

- Core species and build. Dense, stable cores hold screws, resist edge crush, and stay flatter under load. Birch, eucalyptus, and well-graded tropical veneers are known for stiffness and fastener-holding; very light cores are easier to damage, especially at corners and around tie holes.

- Glue line. “WBP” (weather and boil-proof) describes performance, not one single formula. Phenolic or melamine-enhanced systems are common. For repetitive wet conditions, phenolic bonds are the workhorse because the glue line resists alkalinity and temperature swings better than weaker systems.

- Overlay film. The dark film is not only cosmetics it’s the wear layer that fights abrasion and concrete paste. Heavier phenolic overlays (e.g., around 220 g/m²) do a better job resisting scuffing and deliver a cleaner release for architectural pours. Lighter films can still be useful, but they generally trade durability for price.

- Edge sealing. Edges are the weak point. Moisture sneaks in at cut edges and fastener penetrations long before the face fails. Proper factory sealing plus on-site resealing after every cut dramatically slows swelling and delamination.

- Tolerances and flatness. Tight thickness tolerance and solid lay-up reduce “telegraphing” and maintain panel geometry through cycles. That means fewer callbacks and less planing or packing on the next set.

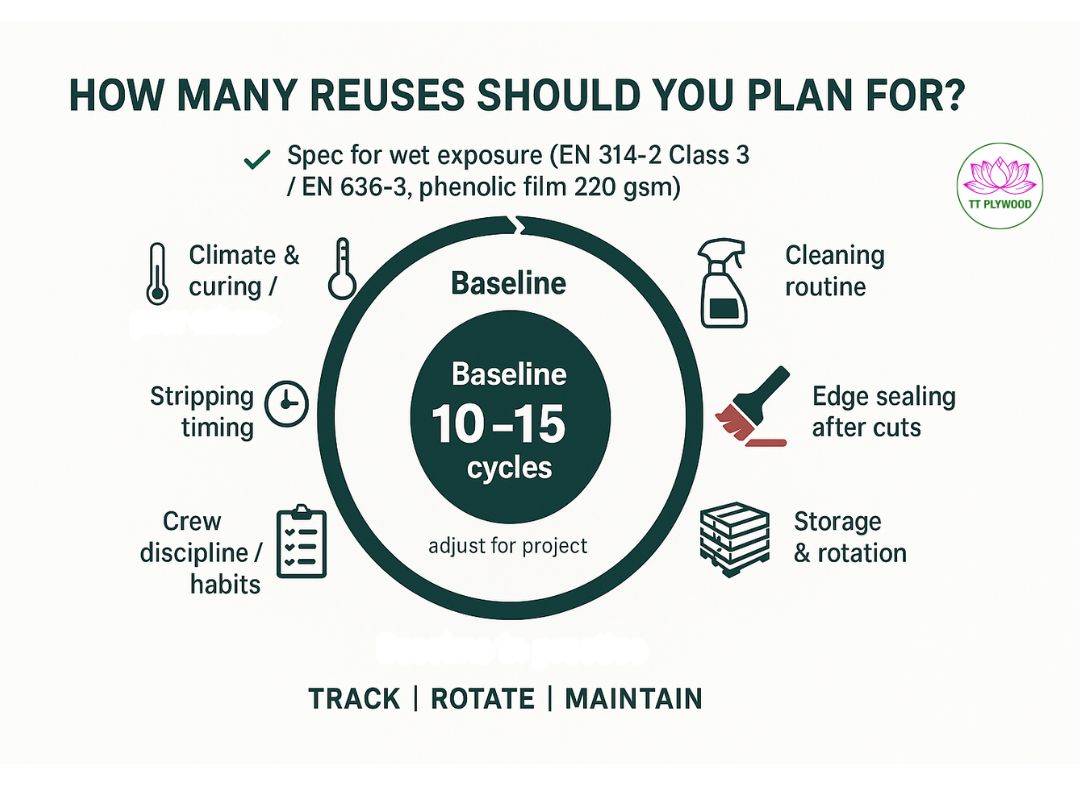

How many cycles should you plan for?

A smart plan is conservative on paper and ambitious in practice. Specify for tough, wet exposure; assume a reasonable, job-specific baseline; and then lift actual cycles with a clean process on site. Climate, pour chemistry, stripping timing, crew habits, and storage conditions all move the needle. Contractors who win on reusability treat their panels like tools, not consumables tracked, rotated, and maintained.

For a deeper breakdown of realistic reuse ranges by panel type, overlay weight, and site practice, check our full guide: How many reuses can you really get from film faced plywood?

Spec like a pro: the buying brief that protects your budget

When you request quotes, be explicit about outcomes, not just size and price. Clarity up front is cheaper than “learning by breakage” on site.

- Service class & bonding: Ask for panels suitable for exterior/humid service with a high-durability glue line (often referenced as EN 636-3 and EN 314-2 Class 3 in Europe).

- Overlay: State the overlay basis weight on both faces. If finish quality and reuse matter, prioritize phenolic film ~220 g/m².

- Core & lay-up: Request dense, uniform core species and stable lay-up to improve flatness and screw holding.

- Edge protection: Require factory edge sealing and order matching edge-seal paint for site cuts.

- Quality paperwork: For projects needing declarations or CE/marking routes, ensure the supplier can provide consistent documentation tied to your spec.

- After-sales support: Ask the mill or supplier for a care sheet (release agent type, cleaning method, storage note). That one page can add multiple cycles over the life of the panel.

Release agents: cheap insurance for the face

A compatible release agent is the simplest way to preserve overlays and finish quality. New panels are “thirsty”—prime them with a uniform first coat before the first pour, then apply thin, even coats on subsequent uses. Avoid puddling; it stains concrete and attracts dust, which acts like sandpaper. If you change the chemistry mid-project, test on one panel first; some agents don’t play nicely with certain films or with the residue from previous products.

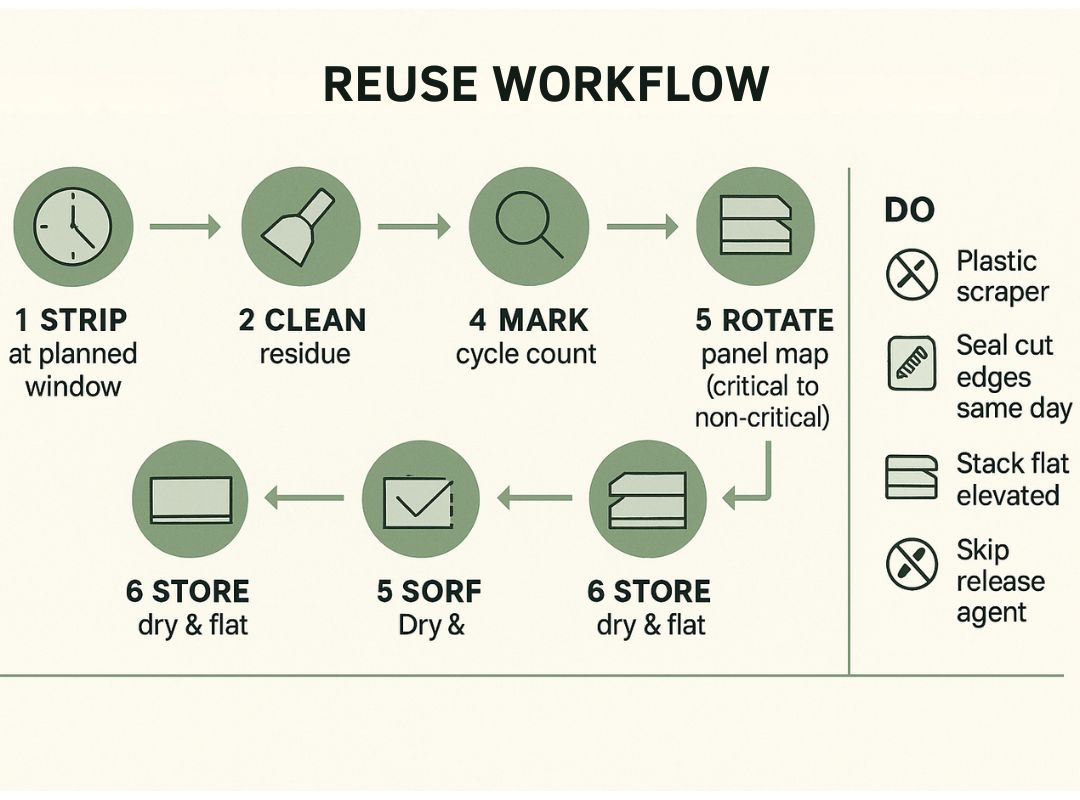

Stripping, cleaning, and rotation

Timing matters. Strip too early and you chip edges; strip too late and paste bonds too hard to the face. As soon as panels are off the mold, remove residue with plastic scrapers or soft pads—never aggressive wire wheels that thin the overlay. Mark panels after each cycle, rotate high-wear zones with less critical areas, and keep a simple panel log. That tiny bit of admin balances wear across the whole batch and squeezes extra turns out of the set.

Pro Tips That Add Extra Cycles

- Prime before first use: Treat new faces with a uniform release coat to stop early “grab.”

- Seal every cut the same day: Tie holes, outlets, and trimmed edges must be resealed before storage.

- Use correct fasteners: Choose length and head profile that clamp without crushing the face; avoid over-driving.

- Protect corners: Corner guards and tight banding prevent fork-tine damage during moves.

- Keep panels dry and flat: Elevate on dunnage, cover from rain and sun, and ventilate the stack.

- Clean, don’t scour: Plastic tools and mild wash keep the film intact; harsh abrasives reduce cycles fast.

- Rotate and record: Swap critical faces to secondary zones and track cycles on each panel.

Storage and transport: where reusability often dies

Most panels fail between pours, not during them. Storing flat on level dunnage keeps sheets from taking a set. Keep ground moisture away never place stacks directly on soil or wet slabs. Cover from rain and ultraviolet exposure; both degrade overlays. On transport, use edge protectors and consistent strapping. A dropped corner can end a panel’s life three pours earlier than planned.

Phenolic vs. melamine film: which makes sense for you?

Think of melamine-overlaid panels as the cost-conscious option for general work and phenolic overlays as the choice for durability and smoother architectural finishes. If your schedule is tight and the number of pours per set is high, the phenolic premium typically pays for itself in extra cycles and fewer rejects. If you pour occasionally with modest finish requirements, melamine films may be a sensible value choice provided you still apply release agents, seal cuts, and store correctly.

Cost-per-pour: a quick mental model

Instead of fixating on price per sheet, calculate price per pour. A more expensive panel that reliably runs extra cycles often beats a cheaper sheet that fails early. Add indirect savings too: fewer panel swaps, less rework on honeycombing or blowholes, and fewer delivery interruptions. Your goal isn’t the cheapest panel—it’s the lowest cost per acceptable surface delivered on time.

On-Site Checklist to Protect Your Investment

- Before pouring: Inspect faces, re-seal cuts, apply a compatible release agent uniformly.

- During forming: Use the right screws, avoid over-driving, and protect corners from impacts.

- Stripping window: Follow the planned strip time; avoid prying at edges use proper wedges and techniques.

- Cleaning: Remove paste promptly with plastic scrapers; avoid wire wheels and harsh scouring.

- Between pours: Dry panels flat, stack on dunnage, cover and ventilate; rotate panels according to your log.

Troubleshooting: common failure patterns and quick fixes

- Edge swelling after two or three pours. Likely unsealed cuts or water ingress during storage. Dry panels thoroughly, trim back to sound material if needed, and re-seal.

- Patchy release and face scuffing. Either the release agent is incompatible or it puddled and trapped dust. Clean the face, test a small area with a different agent, and retrain the spray technique.

- Fastener pull-through or “mushrooming.” Over-driven screws or a soft core. Reduce torque and, for the next purchase, specify a denser core or thicker face veneer.

- Warping between pours. Stacks may be uneven or stored on a wet surface. Re-stack on level dunnage with weight on top; ensure air movement to dry evenly.

Sustainability note: reuse is the greenest spec

Extending panel life is not only good for budgets it’s good for the planet. Each extra cycle reduces material throughput, transport emissions, and site waste. If your client has environmental reporting, document the cycles you achieve. Proving reuse can help win the next tender.

FAQ

1) Is film faced plywood the same as “phenolic plywood”?

Not always. Many film faced panels use phenolic overlays and bonds, but melamine-overlaid options exist. The safest approach is to read the specification and confirm the overlay and glue system, not just the marketing name.

2) Do I really need a release agent if the face is phenolic?

Yes. The film resists wear, but the release agent prevents paste from sticking and preserves the surface. It’s one of the cheapest ways to add cycles.

3) What thickness is best for reuse?

Choose the thickness that meets structural needs and fastener holding on your system. Reusability is more sensitive to overlay quality, glue line, edge sealing, and handling than to thickness alone (once the structural requirement is met).

4) How should I treat cutouts and tie holes?

Seal them immediately after machining. Unsealed edges wick moisture and are often where failures start.

5) Can I mix panel types on the same pour?

You can, but expect different release behavior and finish texture. If appearance matters, keep like-for-like in visible areas and rotate panels within that group.

Want a custom panel spec + handling plan tailored to your exact pour schedule, finish class, and budget? Reach out and I’ll put together a one-page checklist (overlay weight, glue/bonding, core options, release agent guidance, and a storage protocol) so your next batch of film faced plywood delivers more cycles and smoother concrete without over-spending up front.