-

-

-

Total payment:

-

Plywood Grades Explained: BCX vs CDX – Uses, Strength & Buying Guide | TT Plywood

Posted by Thanh Uyên at 25/09/2025

Anyone who has walked into a lumber yard or browsed online suppliers has seen plywood sheets labeled with mysterious codes like BCX, CDX, or AC. To the untrained eye, these combinations of letters might seem random, but they actually represent a universal grading system that helps builders, carpenters, and homeowners choose the right plywood for the right job. Understanding plywood grades is essential for avoiding costly mistakes, ensuring durability, and matching the right material to the right application.

At TT Plywood, we often receive inquiries from international buyers asking: What is BCX plywood? or How does CDX compare to other plywood grades? This article explains these terms clearly, explores how plywood is made, and helps you navigate between different plywood options available at lumber yards worldwide.

How Plywood Grading Works

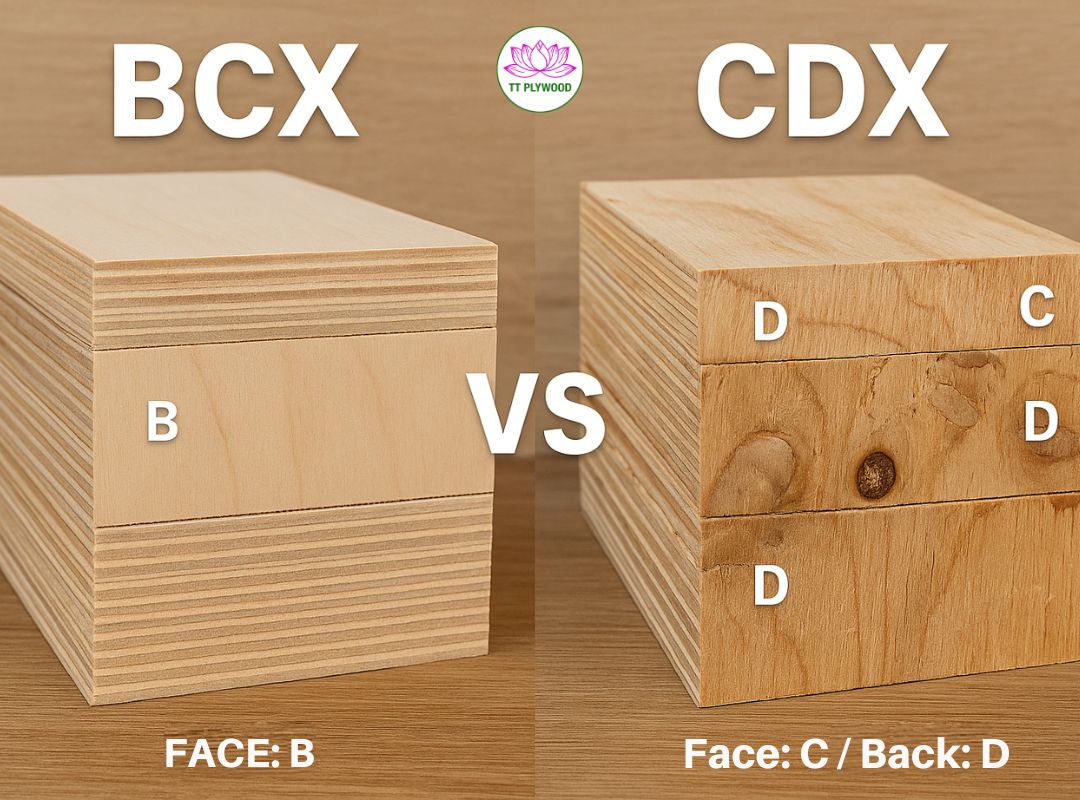

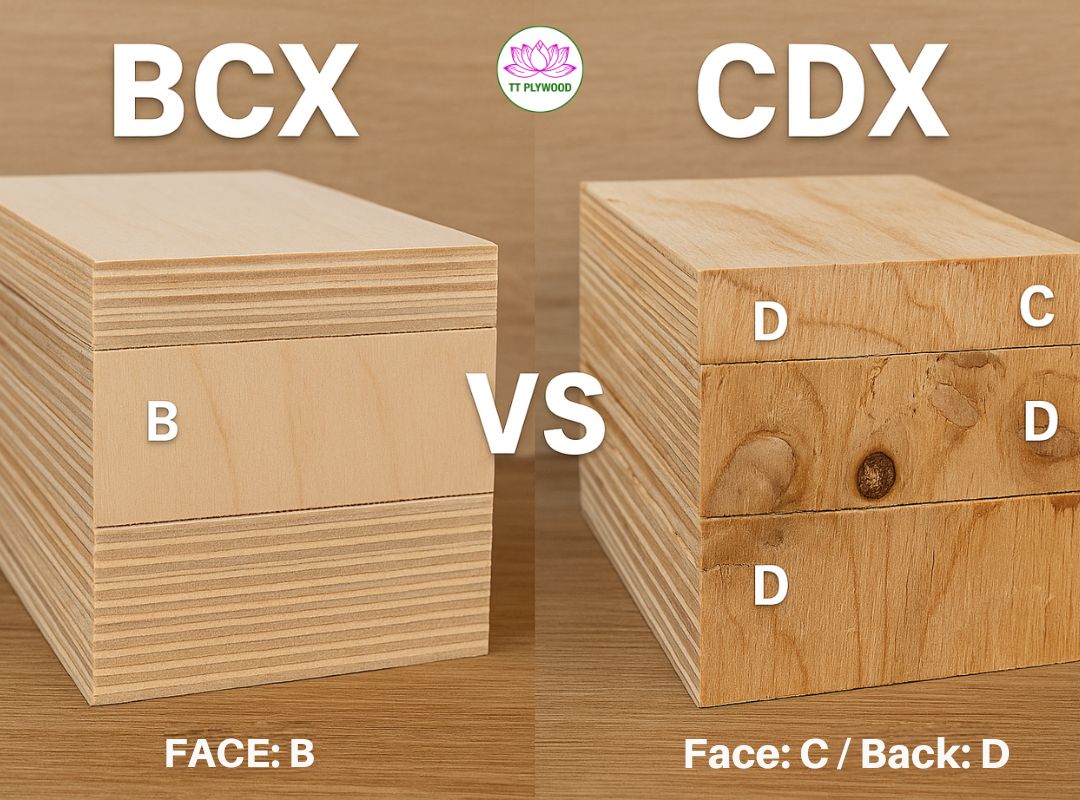

Plywood is produced by pressing together thin sheets of veneer with alternating grain directions. Each veneer sheet is graded based on surface quality, from “A” (the smoothest, defect-free) to “D” (the roughest, with visible knots and repairs). A two-letter grade like BC means one side is higher quality (B) while the opposite side is lower quality (C). When you see an additional “X” in the code, it indicates the use of exterior-grade adhesive, capable of resisting moisture and outdoor exposure.

This grading system is standardized to give buyers an immediate sense of appearance and durability. For example, an AC panel is often chosen for cabinetry, while a CDX panel is typically buried inside a wall or roof where appearance is irrelevant but structural strength is crucial.

👉 Related reading: Understanding Film-Faced Plywood Grades: AA, BB, and CC.

What Is BCX Plywood?

BCX plywood is one of the most common varieties sold in North American lumber yards. The “B” face means it is sanded smooth and contains only small, tight knots or patches, while the “C” back side may have rougher defects that are acceptable for hidden use. The “X” represents exterior adhesive, which makes the sheet suitable for conditions where moisture may occasionally be present.

Because of its balance between finish quality and strength, BCX plywood is widely used for cabinets, shelves, wall sheathing, and flooring underlayments. For global buyers, it provides a dependable middle-ground choice that performs better than CDX in visible applications without being as expensive as premium grades like AC.

👉 See also: Differences Between Baltic Birch and Standard Birch Plywood.

What Is CDX Plywood?

CDX plywood, by contrast, uses lower-grade veneers. The “C” side is rougher, containing knots and patches, and the “D” side allows even more imperfections. Like BCX, it uses exterior adhesive, but it is not intended for projects where the panel surface will be seen. Instead, CDX is an affordable, structural-grade option for roof decking, wall sheathing, and subfloors hidden beneath carpets, hardwood, or tiles.

Builders prefer CDX when budget is a priority and the panel will not be exposed to view. It may not look attractive, but it offers good shear strength, making it suitable for large-scale construction where cost control matters.

Comparing BCX and CDX Plywood

When choosing between BCX and CDX, the main consideration is whether surface finish matters. BCX offers a smoother veneer suitable for painting or semi-visible applications, while CDX is purely structural and rarely used where looks matter. Both use water-resistant glue, but BCX will typically last longer in environments with moderate humidity. Price is also a differentiator—CDX is generally cheaper, making it a go-to material for rough framing.

Plywood Grade Context Beyond BCX and CDX

The industry recognizes many other grades beyond these two. AC plywood, for example, features a nearly flawless surface veneer on one side, making it popular for cabinetry and decorative work. Marine plywood uses special adhesives and higher-quality veneers for resistance to constant moisture, while utility grades like DD are restricted to packaging and temporary structures.

Understanding the full spectrum of plywood grades allows buyers to avoid overpaying for premium panels when a mid-grade option suffices, or conversely, to avoid underestimating the importance of surface finish in projects that demand a polished look.

Plywood vs. OSB: A Common Question

With rising costs, many buyers now compare OSB (Oriented Strand Board) to plywood. Structurally, OSB and plywood are very similar in strength. However, plywood—especially BCX—handles moisture cycles more predictably. OSB tends to swell at the edges when soaked, which can compromise flooring or roofing over time. For this reason, many contractors still prefer plywood sheets such as 1/2 inch plywood 4x8 for roofing and subfloors.

👉 Detailed comparison: Plywood vs OSB: Which Subfloor Material Lasts Longer?.

Buying Guide for Plywood Sheets

If you are at a lumber yard trying to decide between CDX, BCX, or even a 1/4 maple plywood panel, the decision can feel overwhelming. To simplify the process, consider the following points:

Key things to evaluate before buying plywood:

- Project type: Will the sheet be visible or hidden?

- Thickness: Lightweight furniture may use 1/4 inch, while subfloors require 1/2 inch or more.

- Exposure to moisture: Interior or exterior adhesive needs differ.

- Appearance: Smooth faces are needed for painting or staining.

- Budget vs. performance balance: Avoid paying for surface quality you don’t need.

Applications of BCX and CDX Plywood

For clarity, here is where each type is most commonly used:

BCX plywood:

- Shelves, garage cabinets, and semi-visible furniture bases

- Subfloors under tile or carpet

- Packaging and crating for international shipping

- Utility projects that may occasionally encounter moisture

CDX plywood:

- Roof sheathing beneath shingles

- Wall bracing under siding

- Subfloors for large housing projects

- Temporary construction works and formwork

While both types serve important roles, BCX typically fits better for buyers balancing strength and aesthetics, while CDX is the budget-friendly structural workhorse.

How Is Plywood Made?

To understand why these grades exist, it helps to know how plywood itself is made. Logs are peeled into thin veneer sheets using rotary lathes. These veneers are dried, graded, and sorted. Adhesive is then applied between each layer, and the panels are hot-pressed under high pressure and temperature. The result is a sheet that gains strength from alternating grain directions, minimizing warping and maximizing durability.

👉 Step-by-step guide: Birch Plywood Production Process: From Log to Premium Panel.

At TT Plywood, we follow strict international standards such as EN 636, EN 314, and ASTM D6007. Our panels are tested for formaldehyde emissions, adhesive bond strength, and durability to ensure compliance with global regulations like TSCA Title VI.

Case Study: Roberts Plywood and Global Supply

In the United States, distributors like Roberts Plywood have built reputations as reliable suppliers of specialty panels. They serve as intermediaries between manufacturers and end users, ensuring that contractors, architects, and DIY enthusiasts have access to a variety of grades. However, for international buyers looking for bulk shipments or custom specifications, purchasing directly from manufacturers like TT Plywood offers greater flexibility and cost advantages. With global shipping routes from Vietnam to North America and Europe, we provide tailored solutions that meet the diverse needs of construction, furniture, and packaging industries.

Frequently Asked Questions (FAQ)

1. What does BCX plywood mean?

BCX plywood has a B-grade front veneer, a C-grade back veneer, and exterior adhesive (“X”). It is smoother than CDX and suitable for semi-visible applications.

2. What is CDX plywood used for?

CDX plywood is used in structural projects such as roof sheathing, wall bracing, and subflooring where appearance is not important.

3. Is BCX plywood waterproof?

No plywood is completely waterproof, but BCX uses exterior adhesive that provides resistance to occasional moisture. For long-term water exposure, marine plywood or film-faced plywood is a better choice.

4. Which is stronger: OSB or plywood?

Both offer similar strength, but plywood generally performs better in repeated wet-dry cycles, making it more durable for flooring and roofing.

5. Where can I buy high-quality BCX or CDX plywood?

You can source directly from manufacturers like TT Plywood, who supply international-grade plywood tested under EN and ASTM standards.

At TT Plywood, we specialize in exporting high-quality Birch Plywood, Film-Faced Plywood, and engineered products like LVL. Our panels meet FSC, CARB/EPA, EN, and TSCA standards, making them suitable for construction, furniture, and industrial packaging worldwide.

👉 Whether you are comparing BCX vs CDX plywood, sourcing specialty grades, or looking for cost-effective alternatives to Baltic Birch, TT Plywood is ready to support your project.

📩 Contact us today to request a sample, quotation, or consultation with our sales team.